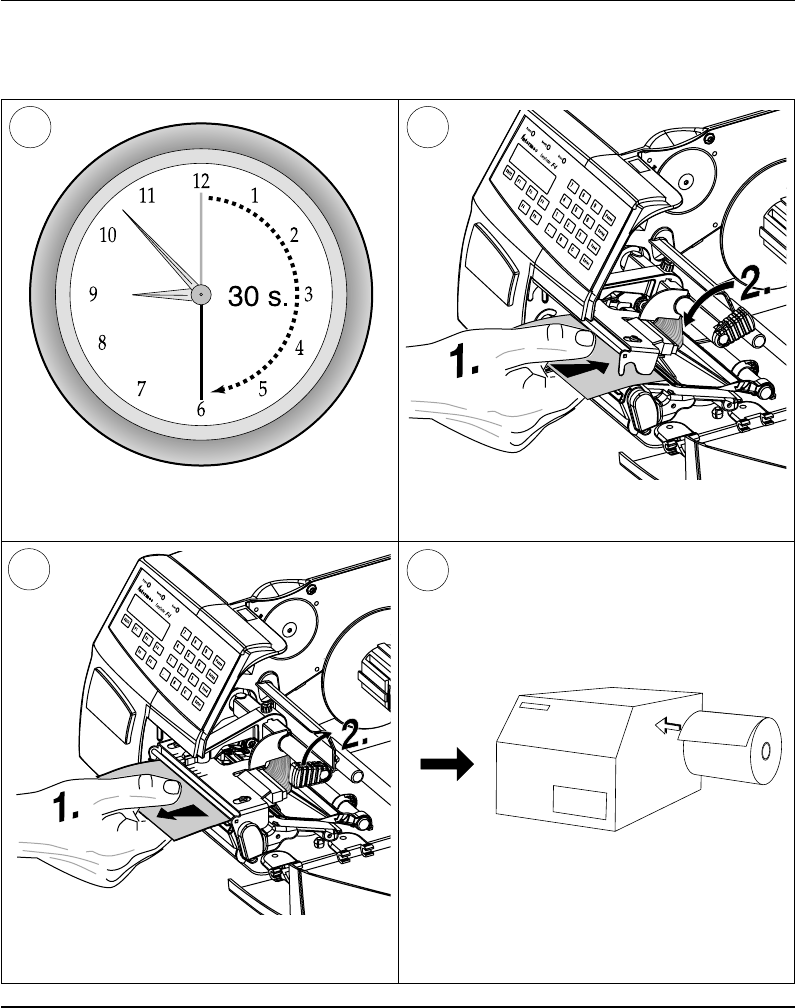

Chapter 11 Maintenance Printhead Cleaning, cont'd. 7 8 Wait for approx. 30 seconds to allow the cleaning fluid to dissolve the residue. 9 Pull out the cleaning card. If necessary, repeat the process with a new cleaning card. 78 Insert most of the cleaning card under the printhead (1). Close the printhead (2). 10 Allow the cleaned parts to dry before loading any paper. Intermec EasyCoder F4 – Installation & Operation Ed.

Chapter 11 Maintenance External Cleaning 1 2 Always remove the power cord before cleaning! 3 Never spray the printer. Protect it from water when cleaning the premises. Intermec EasyCoder F4 – Installation & Operation Ed. 2 Wipe external surfaces with a soft cloth slightly moistened with water or a mild detergent. 4 Never use any sharp tools for removing stuck labels. The printhead and rollers are delicate.

Chapter 11 Maintenance Cleaning the Paper Guides Both parts of the label stop sensor, which controls the paper feed, are covered by plastic guides. The guides are provided with seemingly non-transparent areas, through which the light between the two parts of the label stop sensor is transmitted. These areas (indicated by a shade of grey in illustration #2 below) must be kept clean from dust, stuck labels, and adhesive residue. If the printer starts to feeed our labels in an unexpected way.

Chapter 11 Maintenance Printhead Replacement The printhead is subject to wear both from the direct thermal paper and from the rapid heating and cooling process during printing. Thus, the printhead will require periodical replacement. Time between printhead replacements depends on the print images, the type of paper in use, the amount of energy to the printhead, and several other factors. Note! While replacing the printhead, the power should be switched off. 1 2 Open the side door.

Chapter 11 Maintenance Printhead Replacement, cont'd. 4 3 Remove the paper, if any. 82 Pull the printhead bracket away from the magnet in the pressure arm. 5 6 Disconnect the printhead bracket from the print mechanism – as indicated by the arrows – and pull out the printhead as far as the cables allow. Disconnect the cables from the printhead. Note the snap-lock on the inner connector. Pull at the connectors – not the cables! Snap-lock Intermec EasyCoder F4 – Installation & Operation Ed.

Chapter 11 Maintenance Printhead Replacement, cont'd. 7 Connect the two cables to the replacement printhead. 9 Close the printhead so the magnet engages the printhead bracket. Intermec EasyCoder F4 – Installation & Operation Ed. 2 8 Put back the printhead in reserse order and check that the printhead cables run freely. 10 Load a new supply of paper as described earlier in this manual.

Chapter 12 Adjustments Narrow Labels Adjustment The printer is factory-adjusted for full size paper width. When using paper less than full width, it is recommended to adjust the pressure arm so it becomes centred on the paper. Thereby, an even pressure across the paper is obtained. A poorly adjusted pressure arm may be detected by a weaker printout on the inner part of a less than full width paper.

Chapter 12 Adjustments Label Stop Sensor Position The label stop/black mark sensor (LSS) is a photoelectric sensor that controls the printer's paper feed by detecting gaps between labels, slots in paper strip, or black marks, depending on the printer's setup in regard of media type (see chapter 6 “Setting Up the Printer”). A prerequisite is obviously that the LSS is aligned with the slots or black marks. Thus, the LSS can be moved laterally between 5 fixed positions.

Chapter 12 Adjustments Printhead Pressure The pressure of the thermal printhead against the paper is factory adjusted. However, the use of thicker or thinner paper than normal could require the printhead pressure to be readjusted. Using a flat-tipped screwdriver, turn the adjustment screw clockwise for increased pressure (+), or counter-clockwise for less pressure (-). Print a few labels, preferably test labels (see chapter 6 “Setting Up the Printer”), and check the printout.

Appendix 1 Technical Data Printing Print Technique Printhead Resolution Print Speed (variable) Print Width (max) Print Length (max) Media Width (min/max) Media Width (min/max) Paper Roll Diameter (max) Paper Roll Core Diameter Print Directions Modes of Operation Tear Off Peel Off Firmware Operating System Smooth Fonts Built-in scalable fonts (std) Built-in bar code symbologies (std) Startup Program (std) Physical Measures Dimensions (W x L x H) Weight (excluding media) Ambient Operating Temperature Humidit

Appendix 1 Technical Data Technical Data, cont’d. Sensors Label Gap/Black Mark/Out of Paper Printhead Lifted Controls Control Lamps Display Keyboard Print Button Beeper Data Interfaces Serial Bar Code Wand Electronic Keys Connection for Optional Interface Boards Yes Yes 5 fixed positions 3 2 x 16 character LCD w.

Appendix 2 Media Specifications Direct Thermal Labels Intermec offers two quality grades of direct thermal paper for the EasyCoder range of printers: • Premium Quality: Top-coated papers with high demands on printout quality and resistance against moisture, plasticisers and vegetable oils. Examples... - Top Board - Duratherm II, - Premium - Duratherm II Tag - Duratherm Ltg. - Duratherm IR • Economy Quality: Non top-coated papers with less resistance to moisture, plasticisers and vegetable oils.

Appendix 2 Media Specifications Paper Roll Size Core Diameters: Width: 38 – 40 mm (1.5") or 76.2 mm (3") Must not protrude outside the web. The web must be wound up on the core in such a way that the printer can pull the end of the web free. Roll Max. diameter (internal supply only): - Position 1 152 mm - Position 2 213 mm - Position 3 203 mm Max. width: 114.3 mm Min. width (standard): 25 mm Min. width (Quick-Load): 40 mm Max. web thickness: 175 µm (6.00") (8.38") (8.00") (4.50") (1.00") (1.57") (0.

Appendix 2 Media Specifications Paper Non-Adhesive Strip ⇐ a ⇒ Web Width: Maximum: Minimum (standard): Minimum (Quick-Load): 114.3 mm 25.0 mm 40.0 mm (4.50") (1.00") (1.57") Media Type Setup: • Fix length strip • Var length strip Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 2 Media Specifications Paper, cont'd. Self-Adhesive Strip ⇐ a ⇒ Web Width (including backing paper): Maximum: 114.3 mm Minimum (standard): 25.0 mm Minimum (Quick-Load): 40.0 mm (4.50") (1.00") (1.57") ⇐ b ⇒ Backing Paper The backing paper must not extend more than a total of 1.6 mm (0.06") outside the paper and should protrude equally on both sides. ⇐ c ⇒ Paper Width (excluding backing paper): Maximum: 112.74 mm (4.43") Minimum: 23.8 mm (0.

Appendix 2 Media Specifications Paper, cont'd. Self-Adhesive Labels ⇐ a ⇒ Web Width (including backing paper): Maximum: 114.3 mm Minimum (standard): 25.0 mm Minimum (Quick-Load): 40.0 mm (4.50") (1.00") (1.57") ⇐ b ⇒ Backing Paper The backing paper must not extend more than a total of 1.6 mm (0.06") outside the paper and should protrude equally on both side. Recommended min. transparency: 40% (DIN 53147). ⇐ c ⇒ Label Width (excluding backing paper): Maximum: 112.7 mm (4.43") Minimum: 23.8 mm (0.

Appendix 2 Media Specifications Paper, cont'd. Tickets with Gap ⇐ a ⇒ Web Width: Maximum: Minimum (standard): Minimum (Quick-Load): 114.3 mm 25.0 mm 40.0 mm (4.50") (1.00") (1.57") ⇐ b ⇒ Copy Length: Min. length between slots: 8.0 mm (0.32") Max. length between slots: depends on DRAM size Under favourable circumstances, a minimum ticket length down to 4 mm (0.16") could be used. It requires the sum of the copy length (b) and the detection slit height (e) to be larger than 7 mm (0.

Appendix 2 Media Specifications Paper, cont'd. Tickets with Black Mark ⇐ a ⇒ Web Width: Maximum: Minimum (standard): Minimum (Quick-Load): ⇐ b ⇒ Copy Length: Minimum: Maximum: 114.3 mm 25.0 mm 40.0 mm (4.50") (1.00") (1.57") 20.0 mm (0.8") depends on DRAM size ⇐ c ⇒ LSS Detection Position: Five fixed positions (distance from inner edge of paper): 3 mm (.118") 8 mm (.315") 12 mm (.472") 16 mm (.639") 20 mm (.

Appendix 3 Interfaces RS 232C Interface The EasyCoder F4 has – as standard – two serial communication interfaces: RS 232C on "uart1:" and USB (see next page). Protocol Default setup: Baudrate: Char. length Parity: Stop bits: RTS/CTS ENQ/ACK: XON/XOFF: New Line: 9600 8 bits None 1 Disabled Disabled Disabled (both ways) CR/LF To change the serial interface settings, see chapter 6 “Setting Up the Printer”.

Appendix 3 Interfaces USB Interface The EasyCoder F4 has – as standard – one USB communication port. To use the USB interface for printing from a PC, you need a special USB printer driver installed in your PC. USB = Universal Serial Bus Using an USB Class A - B cable, connect the Class A end to your PC or hub and the Class B end to your EasyCoder F4 printer. USB Class A connector. Connect to PC or hub. USB USB Class B connector. Connect to USB receptacle on the printer's rear plate.

Appendix 3 Interfaces Double Serial Interface Board The EasyCoder F4 can optionally be fitted with an extra double serial interface board, which provides the printer with two more serial ports; "uart2:" and "uart3:". These ports can be configured for various types of serial communication in combination according to the customer's request. Use the Intermec Fingerprint instruction SETSTDIO to select standard IN and OUT ports (by default "uart1:" is both std IN and OUT port)1.

Appendix 3 Interfaces Double Serial Interface Board, cont'd. "uart3:" Serial Port The communication ports "uart3:" uses a male DB 25 connector.

Appendix 3 Interfaces IEEE 1284 Parallel Interface Board The EasyCoder F4 can optionally be fitted with an IEEE 1284-I compatible parallel interface board1. The parallel port is addressed in Intermec Fingerprint as device "centronics:". Select "centronics:" as standard IN port by means of the instruction SETSTDIO (by default, "uart1:" in std IN port)2. Interface Cable Connectors Computer end: Depends on type of host computer.

Appendix 3 Interfaces Industrial Interface Board The EasyCoder F4 can optionally be fitted with an Industrial Interface Board, that provides the printer with one extra serial communication port ("uart2:"), which can be configured for one of the following alternatives RS 232C RS 422 Non-isolated RS 422 Isolated RS 485 This port is identical to "uart2:" on the double serial interface board. The Industrial Interface Board also has a female DB-44 connector with...

Appendix 3 Interfaces EasyLAN 100i Interface Board The Intermec EasyLAN 100i Ethernet interface board provides the printer with a 10BaseT Ethernet or 100BaseTX Fast Ethernet network connection. You can communicate with the printer via a LAN (Local Area Network) or provide the printer with its own home page, so you can reach the printer via internet on the world wide web (www). EasyLAN 100i supports most major computer systems and environments.

Appendix 4 EasySet Bar Code Wand Setup Connection and Operation 1. Connect the optional EasySet bar code wand to the receptacle on the printer’s rear plate. 2. Read the appropriate bar code to set up the printer. Hold the wand like a pencil and move it rather swiftly across the bar code. Connect here! 3. When the bar code has been accepted, the printer emits a short beep and the Ready control lamp on the printer’s front blinks briefly. Intermec EasyCoder F4 – Installation & Operation Ed. 2 4.

Appendix 4 EasySet Bar Code Wand Setup Serial Communication on "uart1:" Baudrate Char. Length Parity 104 Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Serial Communication on "uart1:", cont'd. No. of Stop Bits Reset comm. to default RTS/CTS ENQ/ACK XON/XOFF, Data to Host Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Serial Communication on ”uart1:”, cont’d. XON/XOFF, Data from Host New Line Start- and Stopadjust Tear Off 106 Peel Off Default Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Contrast Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Test Labels Media Width 108 Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Media Length Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Media Type Print Speed 110 Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 4 EasySet Bar Code Wand Setup Paper Type Direct Thermal Printing (Europe) Direct Thermal Printing (USA) Intermec EasyCoder F4 – Installation & Operation Ed.

Appendix 5 RFID Module RFID Module The EasyCoder F4 can optionally be fitted with an Intellitag® 500 RFID (radio frequency identification) board that provides the printer with the means to preprogram Intellitag® 500 RFID SmartLabels when the bar code portion of the label is printed. The RFID board is addressed in Intermec Fingerprint 7.3 or later as device “uart2:” The RFID board does not require connection to any device external to the printer.

Notes Intermec EasyCoder F4 – Installation & Operation Ed.