Specification

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11.

10. Заполните швы между панелями шпаклевкой PUFAS (Füll+Finish). После высыхания и усадки процедуру повторить, затем обработайте швы

шпаклевкой финишной Sheetrock.

12.

Tools and materials that you will need

ARTPOLE DESIGNS ARE PROTECTED BY PATENTS, COPYRIGHTS

AND BY LAW. MANUFACTURING OR TRAFFICKING OF COUNTERFEIT GOODS

SHALL BE LIABLE UNDER CIVIL AND CRIMINAL LAW OF THE RUSSIAN FEDERATION.

Finishing putty

“Sheetrosk”

Protective

lm

Gypsum lling putty

(Full+Finish)

Tools for installation

“Artpole”

LevelScrewdriver

Set of consumables

“Artpole” for 3 m2

шпаклевку гипсовую заполняющую

PUFAS (Füll+Finish)

Countersink

Подготовьте панель к монтажу,

просверлив четыре отверстия на

углах панели, отступив 3-5 см. от края

(в зависимости от дизайна панели).

Рекомендуем использовать зенкер из

набора инструментов “Артполе”, с

помощью которого одновременно

делаются фаски под “шляпки”

саморезов.

Убрав панель, просверлите отверстия по

отмеченым точкам. В готовые отверстия

вставьте пластиковые дюбеля. В случае

монтажа на стену из пеноблоков или ГКЛ

используйте специальные дюбеля дривы из

набора расходных материалов “Артполе”.

Electric saw

3D design wall panels

of non-combustible materials

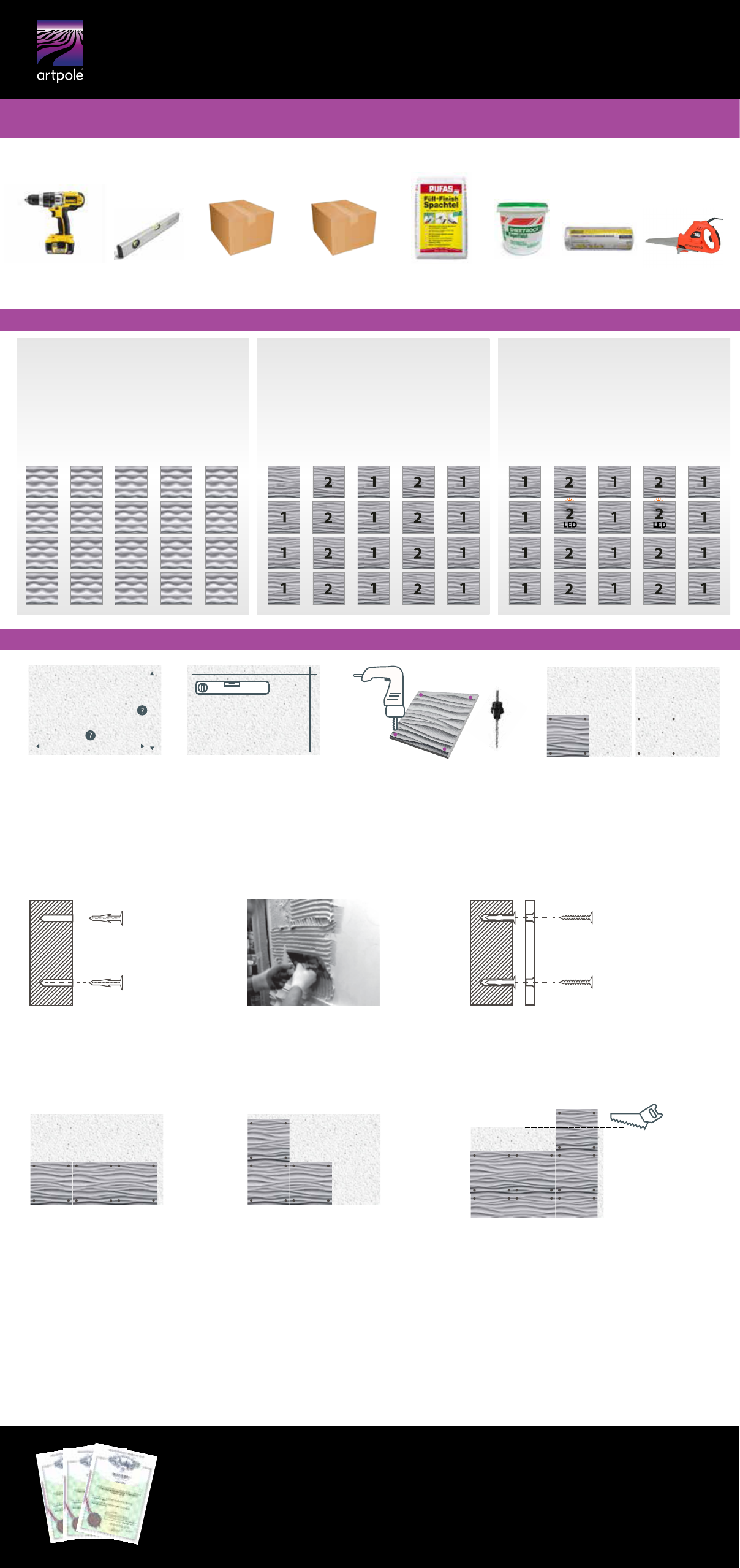

MONO panels

DOUBLE panels Double panels with light

Arrangement of panels

Installation of panels

Instructions for installation of gypsum panels

The simplest type of installation. All panels

are identical and are mounted next to each

other, creating a continuous composition.

A unique type of panel that allows to embed

LED lamps directly into the wall. Installed as

well as the usual double panels. When you

want to use the lightbar, it is simply mounted

in place of the #2 panel.

This type of panels forms an integral gure

only when integrating two panels #1 and #2.

This allows to make the texture on the wall

with fewer repetitions. Prior to the purchase

and installation of these panels calculation of

the number of panels #1 and #2 is required,

since their number may not be equal.

1 Conduct measurements

of the walls to determine

the number of panels

horizontally and vertically.

5 Removing the panel, drill holes at the marked

points. In the nished holes, insert the plastic

dowels. In the case of mounting at the wall of foam

blocks or plasterboard use special dowels “Driva”

from the set of consumables "Artpole."

8 Installation is possible in two ways: a) horizontally; b) by “ladder”. It is more

convenient to begin the installation from the lower left (right) edge of the wall. When

mounting it is necessary to keep the distance between the panels 1-1.5 mm, this can

be achieved using a cardboard rulers with a certain thickness. Further the seams are

wiping with a gypsum putty, if necessary further nal processing is allowed.

10 Fill the joints between the panels with the putty (Full + Finish). After drying and shrinkage, repeat the procedure, then treat the joints with the

nishing putty “Sheetrock”.

11 After all seams are wiped and the putty is dried, treat roughnesses with a ne-grained sandpaper.

12 The panels are ready to be painted and, if necessary (depending on the choice of the nal coating) before painting the surfaces of panels can be

primed. Painting can be done by spray gun, roller or brush.

9 If the remaining section of the wall is not the same

as the size of the panel, it is necessary to measure the

rest of the site and saw o the desired size of the panel

with the electric saw.

6 On the section of the wall,

where it is supposed to install

the panels, apply gypsum

lling putty (Full + Finish)

7 Place the panel to the wall, aligning the holes

in the plate with the holes on the wall and fasten

with screws. Continue installation of panels

horizontally, combining drawing, and then

proceed to the next row.

2 Using a laser or

conventional building level,

determine the ideal

horizontal and vertical

lines, mark them with a

pencil.

4 Place the rst panel to the site of

the wall where you want to start the

installation. Through the made holes

in the panel make pencil marks to

be visible on the wall.

3 Prepare a panel for installation, drill

four holes in the corners of the panel,

retreating 3-5 cm from the edge

(depending on the design of the panel).

We recommend to use countersink from

the set of tools “Artpole” with which

chamfers under the cap screws can be

made simultaneously .

Attention! Screw must pull the plate

to the wall without excessive force

a) horizontally

b) by “ladder”