Data Sheet

MPU-6000/MPU-6050 Product Specification

Document Number: PS-MPU-6000A-00

Revision: 3.4

Release Date: 08/19/2013

45 of 52

Store ESD sensitive devices in ESD safe containers until ready for use. The Tape-and-Reel moisture-

sealed bag is an ESD approved barrier. The best practice is to keep the units in the original moisture

sealed bags until ready for assembly.

Restrict all device handling to ESD protected work areas that measure less than 200V static charge. Ensure

that all workstations and personnel are properly grounded to prevent ESD.

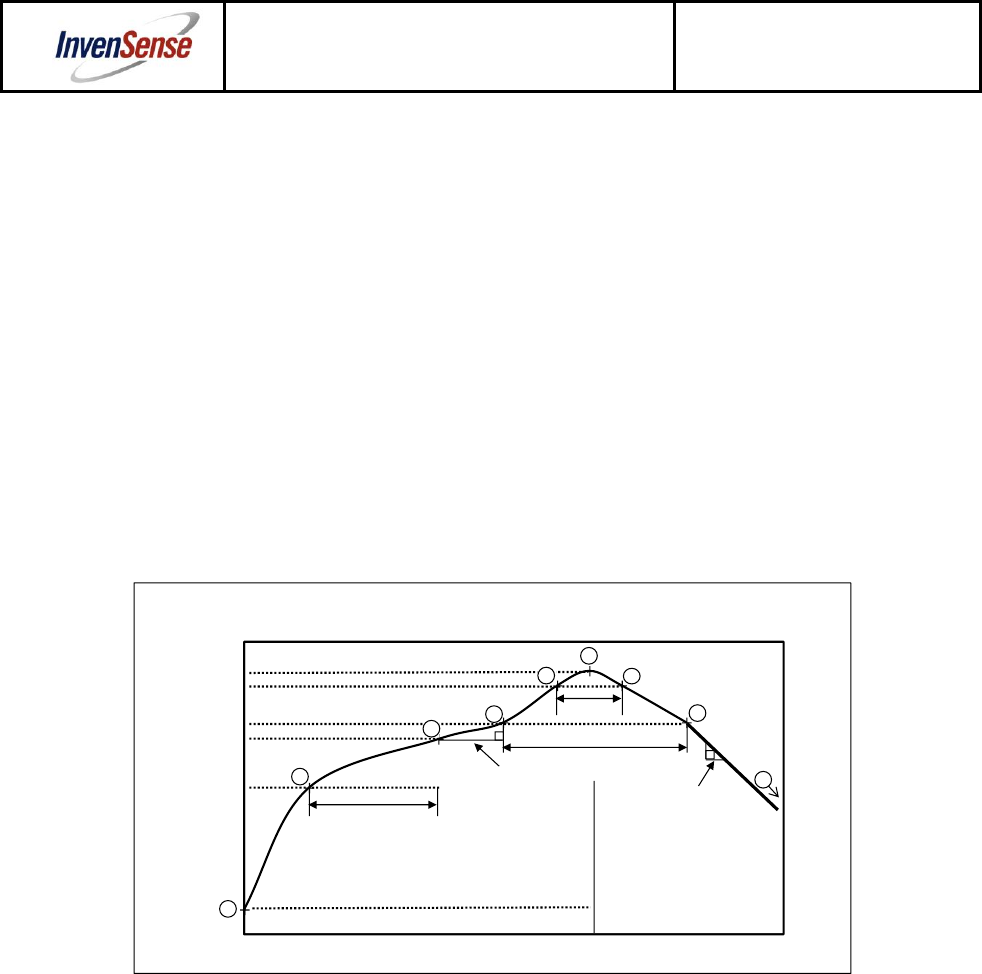

11.4.8 Reflow Specification

Qualification Reflow: The MPU-60X0 was qualified in accordance with IPC/JEDEC J-STD-020D.1. This

standard classifies proper packaging, storage and handling in order to avoid subsequent thermal and

mechanical damage during the solder reflow attachment phase of PCB assembly.

The qualification preconditioning process specifies a sequence consisting of a bake cycle, a moisture soak

cycle (in a temperature humidity oven), and three consecutive solder reflow cycles, followed by functional

device testing.

The peak solder reflow classification temperature requirement for package qualification is (260 +5/-0°C) for

lead-free soldering of components measuring less than 1.6 mm in thickness. The qualification profile and a

table explaining the set-points are shown below:

Temperature [°C]

Time [Seconds]

SOLDER REFLOW PROFILE FOR QUALIFICATION

LEAD-FREE IR/CONVECTION

Preheat

60-120sec

T

smax

T

smin

T

Liquidus

T

Pmin

T

Pmax

Liquidus

60-120sec

10-30sec

T

ramp-up

( < 3 C/sec)

T

ramp-down

( < 4 C/sec)

T

room-Pmax

(< 480sec)

A

B

C

D

E

F

G

H

I