Instructions Manual

4

Copyright © 2011 Star Water Systems. All rights reserved.

5

Copyright © 2011 Star Water Systems. All rights reserved.

PREPARATION

Before beginning installation of product, make

sure all parts are present. Compare parts with

package contents drawing. If any part is missing

or damaged, do not attempt to assemble

the product. Contact customer service for

replacement parts.

Estimated Installation Time: 2 hours.

Tools Required for Installation: Hacksaw,

screwdriver, pliers, pipe vise, pipe wrenches (2),

wire cutters, wire strippers/crimpers, adjustable

wrench (medium-large), Ohmmeter, propane

torch, knife or round file, small weight.

Materials Required for Installation:

Control box for 3-wire plus ground models

(see chart on page 6) Submersible pump cable,

power cable, pressure tank, shrink tube &

butt connectors, 1-1/4 in. check valve, torque

arrestor, hose clamps, pipe fittings, pitless

adaptor or well seal, pressure switch, pressure

gauge, pressure relief valve, tank cross, 1/4 in.

minimum safety rope, electrical tape,. You will

also need either enough 1-1/4 in. Schedule 80

PVC pipe to reach 20 ft. below the static level or

20 ft. below the drawdown level of your well,

or coiled poly pipe rated for 160 PSI. Poly pipe

cannot be used for installations any deeper than

200 ft.

Optional Materials: 1-1/4 in. male barbed

adaptor for use with poly pipe, cable guards

to protect wire inside the well, thread tape and

thread paste.

SUBMERSIBLE PUMP CABLE AND POWER

CABLE SELECTION

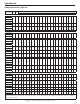

Check cable size against Submersible Wire Size

Chart on page 7. For 3-wire plus ground models,

motor and control box voltage must match.

Submersible power cable must be UL listed for

submersible pump applications. For Canadian

installations, type RWU, TWU, SGOW or SWOW

power supply cable is recommended. Cable is

selected for the maximum pump setting plus the

offset distance to the service entrance.

IMPORTANT: Use of wire sizes smaller than

those specified in the chart will cause low

starting voltage, may cause early pump failure

and will void the warranty. Larger wire sizes

may always be used for better economy of

operation. Be sure voltage at pressure switch or

fuse is between the following limits:

115V Rated - Between 104 & 127 volts

230V Rated - Between 210 & 250 volts

NOTE: A small AWG number, i.e. 10 Ga., is

larger in diameter than a large AWG number,

i.e. 14 Ga.

The National Electric Code (NEC 250-43)

requires a separate ground wire be run

down the well to the submersible pump and

connected to all exposed metal parts of the

pump and motor. Refer to the most recent

National Electric Code (NEC) Article 250

(grounding) for additional information.

NOTE: All wiring should be done by a qualified

electrician.