emission condenser Peltronic Manual

Table Of Contents

- Part I

- Reset / Language selection

- Safety information!

- Technical data

- Use and operation

- Installing a pump in a vacuum system

- Notes regarding the (dry) ice condenser

- Notes concerning the operation of the inlet condenser IK

- Notes concerning the operation of the Peltronic emission condenser

- Notes concerning the operation of pumping units with silencer

- During operation

- Important notes regarding the use of gas ballast

- Important notes concerning the operation of the exhaust waste vapor condenser

- Shutdown & storage

- CVC 3000 Vacuum controller

- Menu guide

- Pump down function

- Vac Control function

- Auto mode

- Program function

- VACUULAN function

- Application examples

- Configuration

- Part II

- Readjustment of CVC 3000

- Calibration in the factory

- Cleaning the pressure transducer

- Interface parameters

- Accessories

- Troubleshooting

- Replacing diaphragms and valves

- Cleaning and inspecting the pump heads

- Disassembling the housing cover at the side of the emission condenser

- Replacing the diaphragm

- Assembling the housing cover at the side of the emission condenser

- Disassembling the housing cover at the side of the ON/OFF switch

- Assembling the housing cover at the side of the ON/OFF switch

- Assembling the fittings

- Cleaning and replacing components

- Notes on return to the factory

- Warranty

- Health and safety clearance form

- EC Declaration of Conformity of the Machinery

page 106 of 120

+ If the old diaphragm is difcult to separate from the diaphragm support

disc, immerse assembly in naphtha or petroleum ether. Do not inhale

vapors!

D

E F

E

F

D

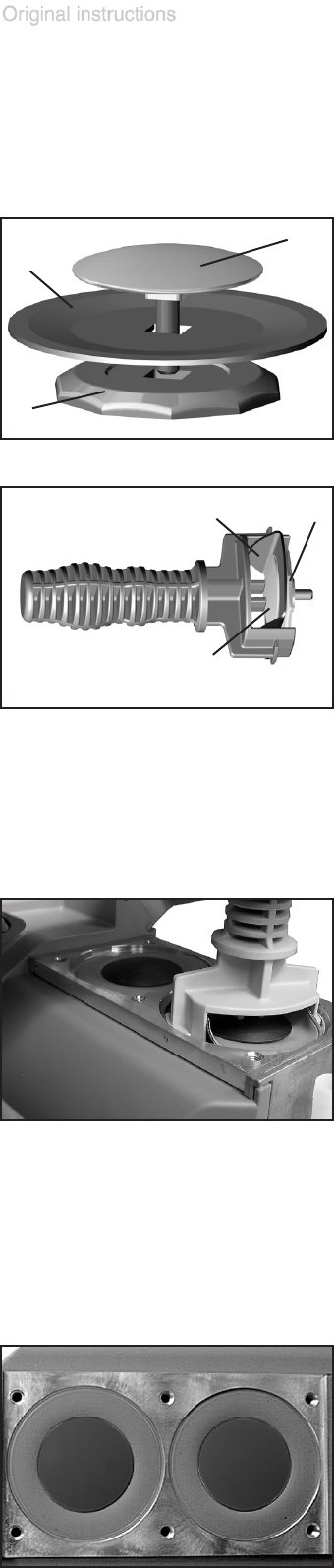

➨ Position new diaphragm (E) between dia-

phragm clamping disc with square head

screw (D) and diaphragm support disc (F).

+ Note: Position diaphragm with pale side

towards diaphragm clamping disc (facing

pump chamber).

+ Make sure that the square head screw of

the diaphragm clamping disc is correctly

seated in the guide hole of the diaphragm

support disc.

➨ Lift the diaphragm at the side. Place the di-

aphragm carefully together with diaphragm

clamping disc and diaphragm support disc

in the diaphragm key.

+ Avoid damage of the diaphragm: Do not ex-

cessively bend or crease the diaphragm.

+ Assemble the original number of washers

(G) between diaphragm support disc (F)

and connecting rod (H).

➨ Screw diaphragm clamping disc (D), dia-

phragm (E), diaphragm support disc (F),

and washers (G) to connecting rod (H).

➨ Optimum torque for the diaphragm support disc: 3 ft

.

lb

f

(4 Nm).

+ If necessary, put the pumping unit in its upright position to screw the

diaphragm clamping disc to the connecting rod. Subsequently lay the

pumping unit again on its side.

➨ Bring the diaphragms (E) into a position, in

which they are in contact with the housing

(I) and centered with respect to the bore.