Instructions Owner manual

Veris Technologies

Pub. #OM 1CM02-1

11

4) If the plunger will not move freely, replace, and coat with di-electric

silicone grease.

5) If the commutator appears to be in good working order, reinstall in the

hub, and adjust until it bottoms against the spindle end. Rotate 1/2 turn

backward to allow adequate clearance. Improper adjustment will result in

premature failure (too little tolerance) or poor continuity (too much

tolerance).

6) Reinstall locking set screw and tighten firmly on top of commutator. The

top of the set screw should be even with the face of the hub. If not,

remove and adjust the commutator inward or outward as necessary.

7) Re-test coulter electrode continuity.

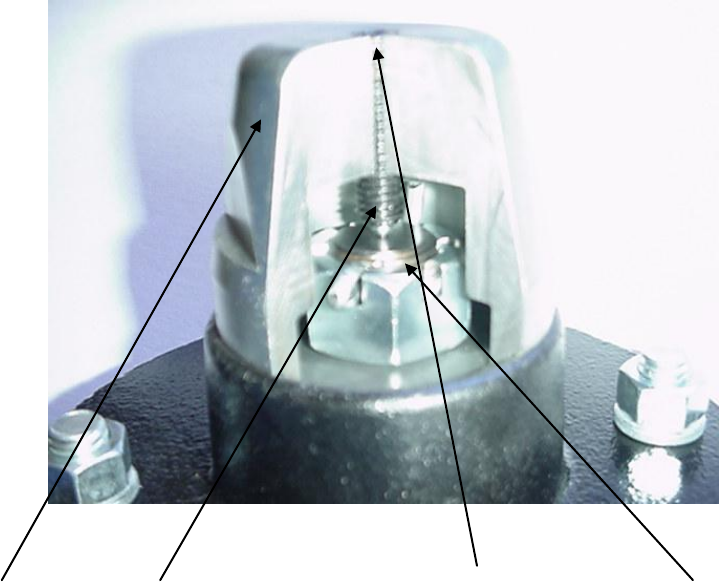

Here is a cut away view of the hubcap assembly

Cap Commutator Set screw Spindle

Note: If you are still unable to obtain favorable resistance readings, check for

excessive corrosion at the coulter blade mounting bolts, or the terminal located

near the coulter pivot.

ANNUAL MAINTENACE

Wheel hubs -- On and annual basis, disassemble, clean, and properly repack the wheel

hubs with suitable wheel bearing grease. It is advisable to replace the seals.

As with any tapered roller bearing, proper pre-load will extend the

life of the assembly. Fully tighten the nut, then rotate backward up to ¼

turn, so that the hub turns freely, without endplay. Install cotter pin, and

reinstall hub cap.