Owner's manual

1

VESTIL MANUFACTURING CORP.

2999 North Wayne St., Angola, IN 46703

Ph: 260-665-9521 Fax: 260-665-1339

Website: www.vestil.com

SAFETY PRECAUTIONS

Read owner's manual completely before operating unit! The

model number and capacity of the table is incribed on its

(green or red) nameplate. Please remember to include these

numbers with any correspondence with your dealer or factory.

Have only qualified personnel perform maintenance and repairs

on this unit.

• The lifting capacity of your unit is based on a uniformly

centered load. This capacity should never be exceeded,

as permanent damage and/or personnel injury could result.

Consult the factory for side or end loading capacities.

• Never lower the unit onto the safety maintenance prop

while the table is loaded. Never go under the platform

unless the maintenance prop is in position.

• Use AW-32 hydraulic oil (or equivalent), or Dexron II

transmission fluid in the tables reservoir. Do not use brake

fluids or jack oils.

• Check the setting and conditions of all safety switches and

stickers frequently.

• Never operate the table if it or any of its components are

in need of repair. Notify the appropriate personnel in the

event of any unusual noises, movements, or noticeable

damage to the table's understructure of controls, or if the

table doesn't respond normally to its controls.

OPERATION

The table is furnished with a remote "deadman" style

control. This type of operation, also called "push to run", allows

the operator to move the unit as much or as little as necessary.

Each press of the air control valves opens a seperate pilot-

operated valve to initaiate the desired movement, and

movement is creased when the valve is released.

The "RAISE" control opens the motor air supply valve

to run the power unit and thereby pump hydraulic fluid to the

cylinder(s). When the table raises to the previously determined

AIR HYDRAULIC SCISSOR TABLE

MODEL AHLT

OWNER'S

MANUAL

Revised 03-00

A company dedicated to solving ergonomic and material

handling problems since 1955

.

AIR HYDRAULIC SCISSOR TABLE

MODEL AHLT

Ergonomic Solutions

Contents

Safety Precautions .......................................... 1

Operation .................................................. 1 & 4

Installation Instructions.................................... 2

Hydaulic Circuit ............................................... 3

Loading Instructions ........................................ 4

Pneumatic/Hydraulic Diagram ......................... 5

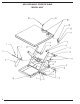

Exploded Parts Drawing ............................... 6

Parts List....................................................... 7

Troubleshooting Guide ........................... 8 & 9

Maintenance & Safety ................................ 10

Warning Label Identification ....................... 11

Warranty ..................................................... 12

upper travel upper travel setpoint, and air valve is closed

which in turn disables the pilot-operated motor air supply valve

and causes the unit to stop.

The "LOWER" control opens a hydraulic "dump"

valve to allow that same oil in the cylinder(s) to return back to

the reservoir. When the unit has completely lowered it will

simply stop lowering.

• The power unit's air motor requires a minimum air supply

of 70 CFM at 70 PSI.

• A good quality air filter/lubricator is required for proper,

long-term operation of the table's power unit. Operation

of this machine without one will void the warranty!

• Refer to the hydraulic troubleshooting guide if problems

arise with the table's operation.

• Regular inspections should be performed on all

pneumatic and hydraulic hoses, as will as a visual

inspection of all structural members, hinges and

components. Check for cracking or scraped paint, oil

leaks, noticeable wear at any pivoting points, loose or

missing fastners and components, etc.