Owner's manual

3

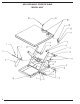

HYDRAULIC CIRCUIT

When the operator wants to raise the unit, he/she presses the "RAISE" button. This opens the

air motor supply valve which turns the hydraulic pump. Oil from the reservoir is drawn in through the

suction filter and into the pump. The pump delivers the pressurized oil through the check valve before

entering the cylinders.

The function of the check valve is to allow the oil to flow in one direction, i.e. towards the

cylinders. It also prevents the flow of oil back into the pump circuit when the pump stops running. This

holds the oil in the cylinders and maintains the desired elevation.

If the load is excessive, and the "RAISE" button is still depressed, pressure will build up in the

circuit between the pump and the cylinders. This forces the "ball" or "poppet" in the relief valve to

unseat allowing the pump out put returns into the reservoir through the return pipe.

When the operator wants to lower the unit, he presses the "LOWER" button. This opens a

hydraulic "DUMP" valve. The poppet in the solenoid valve is unseated and oil now returns from the

cylinders through the flow control valve, return filter, the solenoid valve, oil return pipe, and in the

reservoir.

The flow control valve controls the down speed of the table. It is preset and cannot be

changed.

Releasing the "LOWER" control will de-energize the solenoid, closing the valve poppet. This

prevents the oil from returning to the reservoir and the cylinders will stop retracting. The unit will

maintain that particular elevation.

Cartridge Valves

The lowering valve, as discussed above, is of cartridge construction and is virtually

maintenance free. If there is a faulty operation, check trouble shooting section. To clean the cartridge

valve, follow this procedure:

1.) Use a sharp object and push poppet in from the bottom to open the valve.

2.) Repeat several times while valve is immersed in kerosene or mineral spirits. Blow dry.

3.) Inspect "O" rings and the teflon extrusion washer.

4.) Reinstall. The valve should be tightened to approximately 30 ft. lbs.

Velocity Fuse

There is a brass velocity fuse with a stainless steel spring in the base of each cylinder. In the

event of a hydraulic pump failure, the platform starts to lower at a fast rate. As soon as the descent

speed exceeds the preset speed, the velocity fuse will shut off the oil flow and the platform will remain

stationary until pressure is reapplied. This safety feature reduces the possibility of accidental personal

injury or damage to the table or contents. To reset the velocity fuse just briefly activate pump by

depressing the "RAISE" button.