Technical information

9

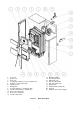

2. Assembly manual

2.1 Boiler construction

The main boiler part is the cast-iron sectional boiler drum made of the grey cast-iron according to

EN 1561, quality 150.

The pressure parts meet the strenght demands according to EN 303-5 - Boilers for central heating – Part 5:

Solid fuel boilers for central heating with manual or automatic feed and max. 500 kW nominal thermal output:

terminology, requirements, testing and marking.

The boiler drum is assembled of sections by means of pressed boiler nipples with 56 mm diameter and

secured by anchor bolts. The boiler sections create the feed space, combustion and ash space, water space

and convectional space. The heating water input and output is situated at the rear boiler part.

There is placed the smoke adapter and heating water connection at the upper part of rear boiler section and

the return water connection at the bottom part. The water connection is possible to connect by means of

thread pipes. The stoking door, ash door and cleaning cover are connected to the front boiler section. Under

the ash pan door there is installed the tilting grate.

There are placed the combustion space barriers behind the clearing cover. The partitions are inserted into

the third flue from above of the boiler drum (see Fig. no. 3a). Their quantity differs for each size of boiler (see

Tab. no. 5).

The whole boiler drum is insulated by the health harmless mineral insulation, which reduces the losses

caused by heat transmission into the environment. The boiler sell is coloured by a good quality comaxit

spray.

Tab. no. 5 Quantity of combustion space barriers

Size of boiler

3 sec

.

4 sec

.

5 sec

.

6 sec

.

7 sec

.

8 sec

.

9 sec

.

10 sec

.

Single channel barier of

combustion space (pc)

1 - - 1 1 - - 1

Double channel barier of

combustion chamber (pc)

- 1 1 1 1 2 2 2

2.2 Rules and directives

The solid fuel boiler can be installed by the company holding a valid certification for its installation and

maintenance. There must be made lay-out according to the valid rules for the boiler installation. Before the

boiler installation to the older heating system the installation company must make the flush (cleaning) of the

whole heating system. The heating system must be filled with water meeting the requirements

ČSN 07 7401, especially its hardness must not exceed the required parameters.

Recommended values

hardness mmol/l 1

Ca

2+

mmol/l 0,3

Concentration of whole Fe + Mn mg/l (0,3)*

*) recommended value

WARNING!!! The use of anti-freeze mixture is not recommended by the manufacturer.

In case of two way safety vent reaction, when there is a possibility of boiler having been filled with

the water, which does not meet the ČSN 077401 requirements it is necessary to change the water in

the heating system so that it meets the ČSN 077401 requirements again.

a) to the heating system

ČSN 06 0310 Heating systems in buildings – Designing and installation

ČSN 06 0830 Heating systems in buildings – protecting device

ČSN 07 7401 Water and steam for thermal energy equipments with working pressure

up to 8 MPa.

EN 303-5 Boilers for central heating – Part 5: Solid fuel boilers for central heating with

manual or automatic feed and max. 500 kW nominal thermal output: terminology,

requirements, testing and marking.

b) to the chimney

ČSN 73 4201 Chimneys and flue gas ducting– designing, implementation and connection of fuel

consumers.

c) regarding the fire regulations

ČSN 06 1008 Fire safety of heat installations.

EN 13501-1 +A1 Fire classification of construction products and building elements – Part 1:

Classification using test data from reaction to fire tests