Instruction Manual

5

REPAIR PARTS LIST - MODEL VG820E

AUTOMATIC WOOD BURNING CIRCULATOR

INTERIOR

16

IMPORTANT

*Size the chimney to the ue outlet on the

stove. (6" outlet = 6" I.D. chimney)

*Avoid using elbows except as necessary

(they reduce dra ).

*Make sure all horizontal runs of connec-

tor pipe go up hill (1/4" elevation for each

horizontal foot).

CHIMNEY CONNECTION

DO NOT CONNECT THIS UNIT TO A

CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

Two basic types of chimneys are approved

for use with solid fuel: Factory-built and ma-

sonry. Factory-built chimney must comply

with UL103HT standard.

Do not expect your stove or furnace to create

dra . Dra is not a function of the appliance.

Dra is purely a function of the chimney.

Modern stoves and furnaces are much more

air-tight and e cient than those of the

past and, therefore require greater dra . A

minimum of .05, measured in water column

(gauges to measure chimney dra are readily

available at stove shops and are economical

to purchase or rent) is required for proper

dra ing to prevent back-pu ng, smoke

spillage, and to maximize performance.

Chimneys perform two functions - one of

which is apparent: e chimney provides

a means for exhausting smoke and ue

gases resulting from combustion of the fuel.

Secondarily, though, the chimney provides

Key Part No. Description Qty.

1 67859 Weldment, Base 1

2 22030 Shield, Second Heat (Included w/ 67859) 1

3 22110 Shield, Heat

(Included w/ 67859) 1

4 68619 Assy., Heat Jacket 1

5 88032 Gasket, Flue Collar 1

6 40246 Collar, Flue 1

7 22090 Curtain, Smoke 1

8 22171 Clip, Smoke Curtain 2

9 40075 Frame, Draft Damper 1

10 23476 Damper, Draft Control 1

11 25550 Pin, Draft Damper 1

12 83890 Clip, Push 1

13 40100 Liner, Front/Back 3

14 40076 Fire, Grate 2

15 40132 Retainer, Brick 2

16 89066 Firebrick (4.5” x 9” x 1.25”) 10

17 891940 Assy., Feed Door

(Complete) 1

- 40199 Feed Door -

Casting Only -

18 88033 Rope Gasket, 3/8” 3.75 ft.

19 891941 Assy., Ash Door

(Complete) 1

- 40289 Ash Door -

Casting Only -

20 88033 Rope Gasket, 3/8” 2.42 ft.

21 83872 Pin, Door -

Short 1

22 23441 Pin, Door -

Long 1

23 83102 Bolt, 1/4-20 x 1.25” CS, Slotted Hd. 2

24 40056 Wheel, Draft 2

25 83415 Nut, 1/4-20 Jam 2

26 25201 Shield, Flame 2

27 83250 Kep Nut, 1/4-20 4

28 40509 Handle, Door 2

29 89523 Handle, Drop Wood 1

30 22434 Latch, Door (2-Step) 1

31 83045 Washer, Flat 2

32 83273 Washer, Spacer 1

33 22108 Latch, Door

(Door Stop) 1

34 23474 Liner, Top 1

35 67444 Ash Pan 1

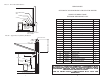

FIG. 6

Cathedral Ceiling - Chimney

Cap Mandatory

PIPE

FLOOR PROTECTOR

REFER TO CHIMNEY

MANUFACTURERS PARTS

AND INSTRUCTIONS

2 FT MIN.

10 FT.

3 FT.

MIN.

BAROMETRIC

DRAFT CONTROL

(OPTIONAL)

11 FT. MIN.

CHIMNEY CAP MANDATORY

DAMPER

FIG. 5

PIPE

FLOOR PROTECTOR

REFER TO CHIMNEY

MANUFACTURERS PARTS

AND INSTRUCTIONS

2 FT MIN.

10 FT.

3 FT.

MIN.

BAROMETRIC

DRAFT CONTROL

(OPTIONAL)

11 FT. MIN.

CHIMNEY CAP MANDATORY

DAMPER

"Dra " which allows oxygen to be continu-

ously introduced into the appliance, so that

proper combustion is possible. As of April 1,

1987, all heaters and furnaces manufactured

by United States Stove Company should be

installed using a factory built chimney that

meets the "Type HT" requirement of UL 103

(when a factory - built chimney is used).

Your smoke pipe should be assembled in

such a way that the male section (crimped

end) of the pipe faces down. Attach each

of the sections to one another with three

equidistant metal screws. Seal with furnace

cement.

IN ORDER TO MAINTAIN WARRANTY, COMPONENTS MUST

BE REPLACED USING ORIGINAL MANUFACTURERS PARTS

PURCHASED THROUGH YOUR DEALER OR DIRECTLY

FROM THE APPLIANCE MANUFACTURER.

USE OF THIRD PARTY COMPONENTS WILL VOID THE

WARRANTY.