Installation Instructions

Install & Maint. Wall Base 15: 02-03-15

Installation and Maintenance Instructions

WALL BASE

NOTICE TO INSTALLER

This brochure contains important installation, maintenance and warranty information as well as cautions and warnings. Our warranty will become effective only if

these instructions are followed in every respect. FOR A COMPLETE STATEMENT OF VPI’S WARRANTY, contact: VPI, Manager, Customer Service, P.O. Box

451, Sheboygan, WI 53082-0451. PLEASE MAKE CERTAIN THESE INSTRUCTIONS RE PLACED IN THE HANDS OF THE FLOOR OWNER.

Please note: In all cases, installations should comply with procedures outlined in ASTM Standards for installation, at a minimum. For procedures specific to VPI

products, please refer to the instructions below or at www.vpicorp.com/product-installation-maintenance, for the most up-to-date recommended installation techniques.

Read the complete instructions before beginning the installation.

GENERAL

The wall surface must be thoroughly dry, smooth, and free from

dirt, wallpaper, vinyl wall covering, grease, old adhesives, and other

extraneous material. DO NOT apply directly over outside walls in

contact with earth (such as unfurred basement walls) or over ceramic

tile, metals, or other impervious surfaces because poor adhesion may

result.

Maintain the wall base, adhesive, and room air at a uniform

temperature of at least 70°F for 24 hours prior to, during, and 48

hours after the installation. Rolled wall base should be unrolled and

allowed to lie flat for 24 hours prior to the installation to regain its

normal shape.

Use only VPI #600 wall base adhesive carefully following the

directions on the container label. THE USE OF ANY OTHER

ADHESIVE WILL VOID VPI’S WARRANTY.

INSTALLATION OF BASE

Spread the adhesive either on the back of the base or on the wall

using a triangular notched trowel or cartridge gun. Trowel notches

should be 3/32” deep by 3/32” wide with 3/32” flats. If applying

adhesive with a cartridge gun, use a 2-hole nozzle for 2 ½” base, a 3-

hole nozzle for 4” base, and a 5-hole nozzle for 6” base.

Apply the adhesive at least ¼” from top of base if using a trowel

and 1” from top of base if using a cartridge so that adhesive does not

seep out as the wall base is rolled.

Bond the wall base within 20 minutes of the adhesive application.

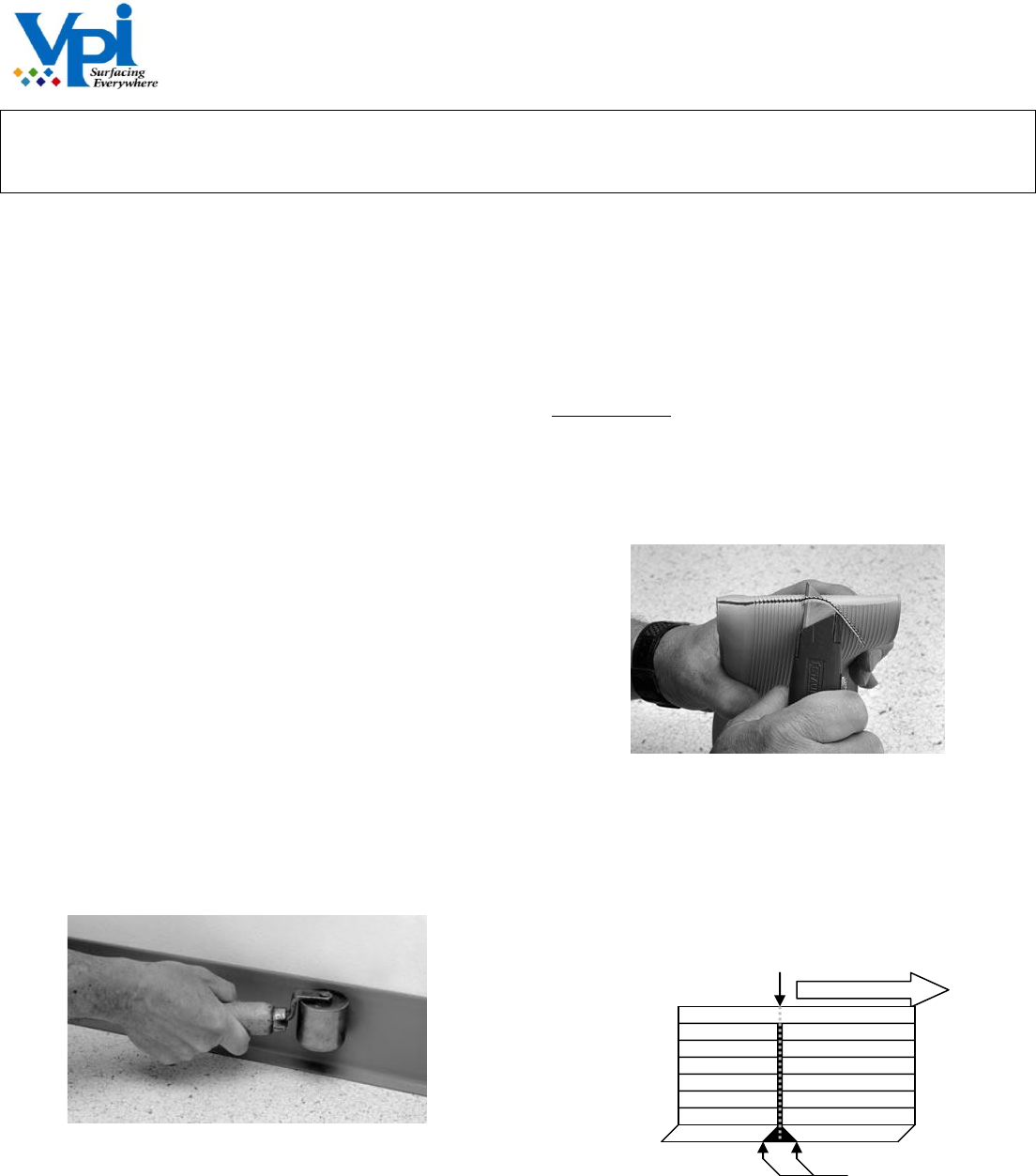

Roll thoroughly with a hand roller immediately after applying the

wall base to the wall (Figure 1). If roller is unavailable, wipe the wall

base with a soft cloth, firmly pressing the base against the wall. Base

applied to curved or irregular surfaces may require bracing until the

adhesive sets.

(Figure 1)

If the wall or floor surface is uneven, it may be necessary to trim

the edges before installing adjoining pieces of base. Use a razor-type

utility knife, cutting the wall base from face to back.

Immediately remove excess adhesive from the base or the wall

with water. Excess adhesive may leave a stain if not removed

promptly.

Avoid exposure of base to excessive heat, such as from direct

sunlight, until the adhesive has completely set.

CORNERS

Preformed outside corners are available – 2 ½”, 4” and 6” if

desired. However, both outside and inside corners can be formed

easily from standard 4-foot lengths or rolls.

Outside Corners – Suggested Method

When you come to an outside corner, butt the next section of base

to the last installed section (or continue to the corner when using

coils). Make sure the base is in the proper position on the wall as you

would install it.

1. Using a pen or pencil, mark the base of the base using the wall

as a guide. This will give you the correct contour of the wall.

(Figure 2)

2. Fold the wall base at the line, face in, and shave the back of the

wall base while folded (Figure 2), removing the line and

approximately 1/8” of base material on either side of it. If you

are using a topset gouge to make these cuts, turn the base face

down and make your cut starting at the top and working down to

the bottom (Cut #1). Note: Always gouge on the side of the line

in the direction the base will be going.

Important: The depth of this area at its deepest point should not

exceed 20% of the base thickness.

3. To ensure that the toe sits flush against the floor, the initial cut

(Cut #1 – Figure A) can be widened on either side of the line

(Cut #2 – Figure A) near the bottom of the base, though this cut

is optional. Make the cut (gouge) downward, widening the

initial cut to approximately one half inch at the bottom. This

will ensure there is no pressure of the toe against the floor

surface.

Direction of Installation

Cut #1

Cut #2

(optional)

(Figure A)