Owner`s manual

5

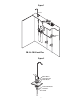

I. Installing the feed water valve

The saddle tapping valve which is supplied is designed to be

used on 3/8” - 1/2” OD soft copper tubing (plain or chromed)

and rigid metal pipe. Do not use with flexible ribbed tubing

because it requires special hardware. Optional feed valves should

be used for this purpose.

IMPORTANT: Some local plumbing codes may prohibit the use of

saddle-type valves. In this case, optional feed valve assemblies

should be used.

Soft Copper Tubing Installation:

A) Turn off the cold water feed valve under the sink, or the

main feed valve for the house.

B) Before installing the saddle tapping valve, make sure the

piercing lance does not protrude beyond the rubber gasket.

See instructions on bag.

C) Place saddle tapping valve around the copper tubing and

tighten the mounting screw until the valve is tight. Be

careful not to deform the copper tubing (see Figure 3).

D) To pierce the soft copper tubing, turn the handle clockwise

until it is firmly seated. The valve is closed in this position.

E) Turn on the main supply valve to pressurize cold water line.

Check for leaks.

F) Connect a length of 1/4” orange tubing to the feedwater

valve, using the insert, plastic sleeves and brass

compression nut.

Rigid Metal Pipe Installation:

A) Turn off the cold water feed valve under the sink, or the

main feed valve for the house.

B) Drill a 3/16” hole at the desired location on the metal pipe.

To prevent shock hazard, use a battery operated drill.

C) Turn the saddle tapping valve clockwise to expose the

piercing lance beyond the rubber gasket no more than 3/16”.

D) Place saddle tapping valve around the copper tubing

making sure the piercing lance is located in the hole and

tighten the mounting screw until the valve is tight (see

Figure 3).

E) Turn saddle valve handle clockwise to close valve.

F) Turn on the main supply valve to pressurize cold water line.

Check for leaks.

G) Connect a length of 1/4” orange tubing to the feedwater valve,

using the insert, plastic sleeve and brass compression nut.

J. Make tubing connections

NOTE: With all of the components in place, the tubing connections

can be made. Be sure to arrange the tubing so that there are no

sharp bends. Leave some “play” in the tubing for ease of servicing.

NOTE: Try to keep the tubing from the filtration system to the

faucet as short as possible to ensure good water flow.

1) Connect the 1/4” orange tubing to the “Push In” male

connector on the inlet side of the filtration assembly (refer

to Figure 4 on the use of “Push In” plastic fittings).

2) Connect the 1/4” blue tubing from the faucet to the

“Push In” fitting attached to the outlet connection on the

filtration assembly.

K. Installing and replacing filter cartridges

NOTE: In order to ensure proper performance, it is essential

that the filters be installed in the correct location. Use the icon

coded labels to match the filter cartridges with their correspon-

ding filter head.

1) Close the feed water valve and lift up the faucet handle. Wait

approximately 10 seconds for the system to depressurize.

2) Twist the filter cartridge 1/4 turn to the left so that the ears

on the cartridge are able to disengage from the head.

Firmly pull the cartridge downward to remove it from the

head. It may be necessary to twist the cartridge slightly

from side to side to help free it from the head.

3) Remove the new filter cartridge from its sanitary sealed

wrapper. (Double check to see that it is the correct

replacement filter cartridge by comparing the labels.)

4) Using either tap water, food grade silicone lubricant or

glycerine, lubricate the o-ring seals to make cartridge

insertion easier.

5) Line up the cartridge ears, insert the cartridge and push it

up into the head until it is firmly seated. Twist the cartridge

1/4 turn to the right to lock it into place.

6) Open the feed water valve and carefully check for leaks.

7) Allow system to operate with the faucet open for at least 10

minutes. This will allow the cartridge to properly flush prior

to use.