Single Stage Operation Oil Burners Installation & Operating Manual

3223

12

GB

BURNER ADJUSTMENT TABLE

NON-RETROFIT APPLICATIONS

If this burner is being installed in a packaged unit (i.e. Burner comes with a boiler or furnace), follow the instal-

lation and set-up instructions supplied with the heating appliance, as settings will differ from those shown in

this manual.

Note: Any approved oil burner nozzle type, angle and manufacturer maybe used, as long as input is corresponding the

correct BTU/hr. or US gph input rating of the appliance.

COMBUSTION CHAMBER

Follow the instructions furnished by the boiler/furnace manufacturer. Size retrofit application according to the appropri-

ate installation codes (e.g. CSA B139 or NFPA #31).

BURNER START-UP CYCLE

NOTE:

The above set up charts are a starting point only.

The burner and appliance must be properly set up using proper combustion testing equipment.

Normal Lock-out, due to light-failure

Thermostat

Motor

Ignition transformer

Valve

Flame

Lock-out lamp

~ 12s ~ 12s ~ 5s

D5229

8000-5800 8000-5900

C8512520 C8512521

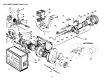

Riello 40

Series

F5

F5 Factory

preset *1

F5 Factory

preset *1

F5 Factory

preset *1

Boiler UO3 UO3 UO4 UO5

Input GPH 0,8 1,0 1,2 1,4

Nozzle Delavan .65 X 70°B .85 X 60°B 1.00 X 70°B 1.10 X 70°B

Pump Pressure PSI 150 145 145 160

0134

2.75 2.8 2.9 2.9

Air tube length inches 8 8 8 8

Ait tube insertion inches 4 1/4" 4 1/4" 4 1/4" 4 1/4"

*1 Nozzle pre-installed at factory.

Burner Model

Turbolator Setting

Air Gate Setting

C8512519

Weil McLain Part No.

Riello Part No.

RIELLO BURNER SET UP SHEET

8000-5700