2-1/2 IN. THICKNESS PLANER Model # 6550 bit.ly/wenvideo IMPORTANT: Your new tool has been engineered and manufactured to WEN’s highest standards for dependability, ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged, trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use your tool properly and for intended purpose, you will enjoy years of safe, reliable service.

TABLE OF CONTENTS 2 3 4 5 7 7 9 12 15 18 Technical Data General Safety Rules Specific Safety Rules For Planer Electrical Information Know Your Planer Assembly and Adjustments Operation Maintenance Exploded View and Parts List Warranty TECHNICAL DATA Model Number: Motor: Cutterhead Speed: Cuts Per Minute: Feed rate: Maximum Depth of Cut: Table Size: Extension Table Size: Base Size: Workpiece Width (max.): Workpiece Thickness (max.

GENERAL SAFETY RULES Safety is a combination of common sense, staying alert and knowing how your item works. SAVE THESE SAFETY INSTRUCTIONS. WARNING: To avoid mistakes and serious injury, do not plug in your tool until the following steps have been read and understood. 1. READ and become familiar with this entire instruction manual. LEARN the tool’s applications, limitations, and possible hazards. 2. AVOID DANGEROUS CONDITIONS. Do not use power tools in wet or damp areas or expose them to rain.

GENERAL SAFETY RULES 14. NEVER STAND ON A TOOL. Serious injury could result if the tool tips or is accidentally hit. DO NOT store anything above or near the tool. 15. DO NOT OVERREACH. Keep proper footing and balance at all times. Wear oil-resistant rubber-soled footwear. Keep the floor clear of oil, scrap, and other debris. 16. MAINTAIN TOOLS PROPERLY. ALWAYS keep tools clean and in good working order. Follow instructions for lubricating and changing accessories. 17. CHECK FOR DAMAGED PARTS.

SPECIFIC RULES FOR THE PLANER 6. Keep hands clear of all moving parts. 7. Do not force cut. Slowing or stalling will overheat motor. Allow automatic feed to function properly. 8. Use quality lumber. Blades last longer and cuts are smoother with good quality wood. 9. Do not plane material shorter than 15”, narrower than 3/4”, wider than 12-1/2” or thinner than 1/2”. 10. Never make planing cut deeper than 3/32". 11. For workpieces longer than 24", use material support stands. 12.

ELECTRICAL INFORMATION WARNING: This tool is for indoor use only. Do not expose to rain or use in damp locations. Guidelines for using extension cords Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows the correct size to be used according to cord length and nameplate ampere rating.

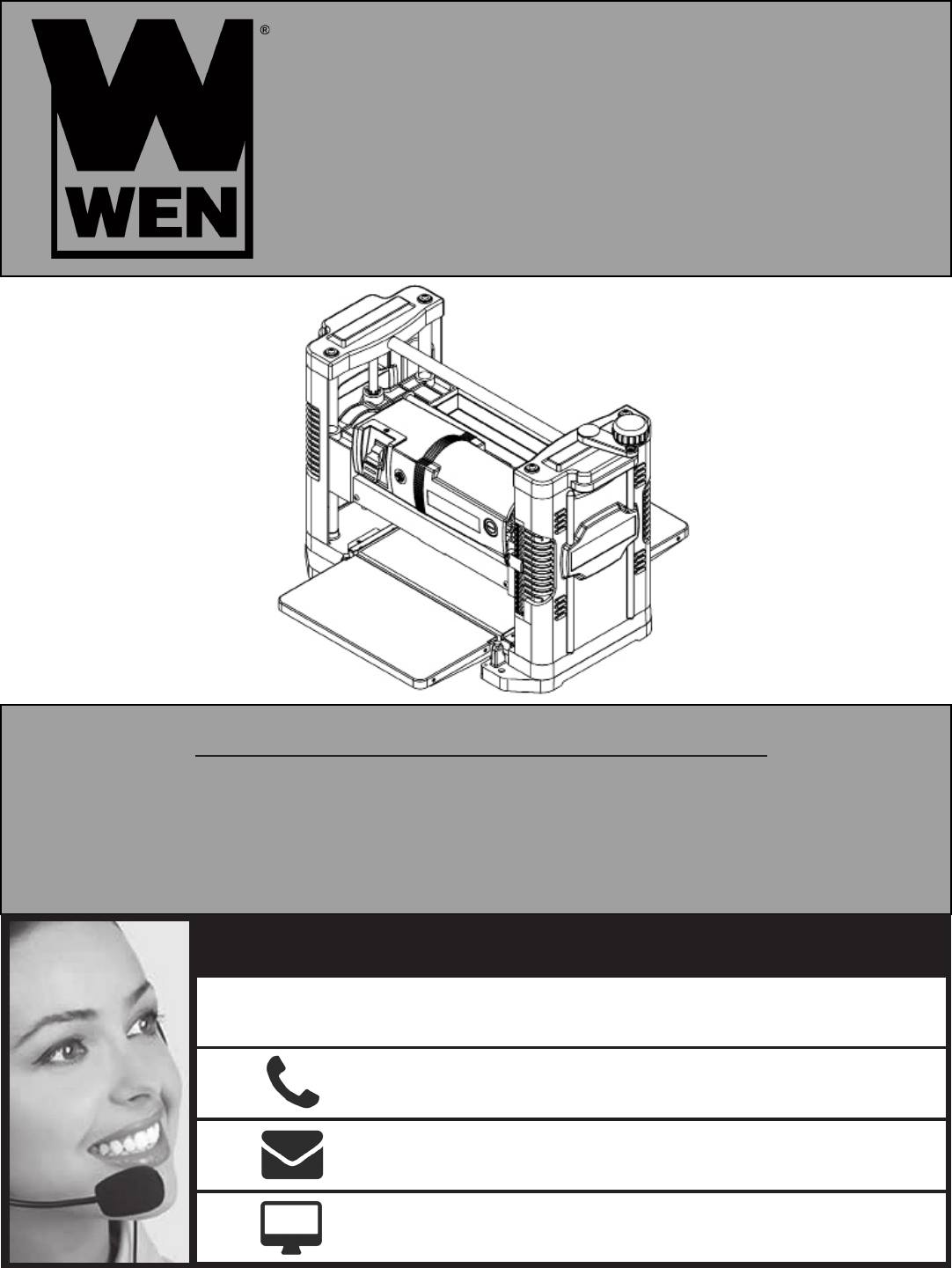

KNOW YOUR PLANER Depth Adjusting Handle Carrying Handle Switch Circuit Breaker Extension Table ASSEMBLY AND ADJUSTMENTS UNPACKING (FIGURE 1) IMPORTANT: Remove protective paper from the table before operating the unit. The planer comes assembled as one unit. Additional parts which need to be fastened to planer should be located and accounted for before assembling.

ASSEMBLY AND ADJUSTMENTS INSTALL DEPTH ADJUSTING HANDLE (FIGURE 2 & 3) The handle and knob should be installed to top-right of the planer. Insert the handle with the knob onto the elevation screw’s top. Secure handle with bolt using T-handle wrench provided. Insert plug into handle to cover bolt. Figure 2 Figure 3 ATTACH DUST CHUTE (FIGURE 4) Planer is best used along with a dust collector. Dust chute is included. The dust chute is mounted to the rollercase using two thumb screws.

OPERATION WARNING: Do not connect planer to the power source until all assembly steps have been completed. The WEN® 12-1/2" Planer planes soft and hardwoods up to 6" thick and 12-1/2" wide. Wood feeds into the twoblade cutterhead by rubber infeed/outfeed rollers. Planer can take cuts up to 3/32" per pass at 26 feet per minute. ON/OFF SWITCH (FIGURE 6) The ON/OFF switch is located on the front of the planer motor. To turn the planer ON, move the switch to the up position.

OPERATION DEPTH OF CUT (FIGURE 8) Depth-of-cut is adjusted by raising or lowering the rollercase using handle. Each full rotation of the handle moves the rollercase 1/16". Quality of thickness planing depends on the operator’s judgement about the depth of cut. Depth of cut depends on the width, hardness, dampness, grain direction and grain structure of the wood. Maximum thickness of wood which can be removed in one pass is 3/32” for planing operations on workpieces up to 5” wide.

OPERATION FEEDING WORK The planer is supplied with planing blades mounted in the cutterhead and infeed and outfeed rollers adjusted to the correct height. Planer feed is automatic; it will vary slightly depending on type of wood. • Feed rate refers to the rate at which the lumber travels through the planer. • Align the work perpendicular to the rollercase so that the work feeds through the planer straight. • Raise/lower rollercase to produce the depth of cut desired.

MAINTENANCE CHECK FOR WORN BLADES Condition of blades will affect the precision of cuts. Observe the quality of the cut that the planer produces to check the condition of the blades. Dull blades will tear, rather than sever wood fibers and produce fuzzy appearances. Raised grain will occur when dull blades pound on wood that has varying density. Raised edges will also be produced where the blades have been nicked.

MAINTENANCE BRUSH INSPECTION AND REPLACEMENT WARNING: Turn planer off and disconnect from power source before inspecting or replacing brushes. Brush life depends on amount of load on motor. Regularly inspect brushes after 100 hours of use. Brushes are located on either side of planer motor, on both the front and rear side of the planer. • Loosen brush cap and carefully remove brush from motor. • Replace brushes if spring is damaged. • Replace brushes if carbon is worn.

MAINTENANCE LUBRICATION Motor and cutterhead bearings are sealed and need no lubrication. Gears and elevation screws should be cleaned of debris and greased as needed. CLEAN PLANER Keep planer clean of any wood chips, dust, dirt or debris. After 10 hours of operation, the chains and gears should have wood chips, dust and old grease removed. Use common automotive bearing grease to lubricate all chains and gears. Be sure all chains and gears have plenty of grease.

EXPLODED VIEW AND PARTS LIST Figure 13 - Base 15

EXPLODED VIEW AND PARTS LIST FIGURE 13 - BASE Item # 1 1A 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Stock # 6550-101 6550-101A 6550-102 6550-103 6550-104 6550-105 6550-106 6550-107 6550-108 6550-109 6550-110 6550-111 6550-112 6550-113 6550-114 6550-115 6550-116 6550-117 6550-118 6550-119 6550-120 Description Screw Flat washer 6 Left Cap Cotter Pin Roller Handle Assembly Right Cap Grip Elevating Nut (RH) Left Side Cover Bolt Spacer Elevating Screw (LH) Column Screw Guide Table Elevating Screw (RH) E

EXPLODED VIEW AND PARTS LIST Figure 14 - Roller Case 17

LIMITED TWO YEAR WARRANTY WEN Products is committed to building tools that are dependable for years. Our warranties are consistent with this commitment and our dedication to quality. LIMITED WARRANTY OF WEN CONSUMER POWER TOOLS PRODUCTS FOR HOME USE GREAT LAKES TECHNOLOGIES, LLC (“Seller”) warrants to the original purchaser only, that all WEN consumer power tools will be free from defects in material or workmanship for a period of two (2) years from date of purchase.