Technical information

INFORMATION

14 April 2010 / W-SQ20 for mobile applications / EN

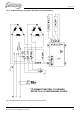

2.5.8 Remote control

All wiring connections from the remote control to the board

are made by plug in connectors.

An intermediate communication cable is in the standard

supply. If necessary an optional longer 8 wire

communication cable can be connected if the standard

length does not suit the required distance. Numerous

remote control units can be put in parallel by using the

connectors on the back of the units. (Refer to installation

instructions)

2.5.9 Hour counter

The remote control offers several timer functions that

helps to schedule maintenance.

2.5.10 Load indicator

On the remote control the load will be indicated on the

display and by the LED-bar. The load is measured by

current transformers on the alternator. All phases are

monitored and overload of all phases or just one or two

phases will provoke an alarm or even shut down when the

alarm is ignored.

2.5.11 Fuel specification

The engine must only be used with diesel fuel oil which

conforms to the standards for use in modern diesel

engines. Fuel free from water and contaminants is of the

utmost importance.

2.5.12 Oil information

1 Specification:

The oil must be suitable for oil changes as specified in

the maintenance chapter. The Mitsubishi engine must

be run on heavy duty lubricating oil meeting the

requirements of API class CD, CF or CF_4.

It is very important to use the correct oil

specification. Very often local oil suppliers

recommend a higher class, because they

assume that a higher class is allowed. This is

not the case. One should not follow these

recommendations.

Using the wrong specification will cause high

oil consumption.

2 Oil viscosity:

We recommend a multigrade oil 15W40.

3 Oil capacity:

Excluding the oil filter the content of the crankcase is

9 l. Including the oil filter it is 9.3 l.

Do not overfill with lubricating oil as this may have a

detrimental effect on engine performance

4 Oil pressure

• Minimum at idle 98 kPa (1 kgf/cm²/14psi) (1 bar).

• At 2230 rpm ±300 kPa (3 kgf/cm²/45 psi) (3 bar).

2.5.13 Cooling liquid

The engine is cooled by cooling liquid. The capacity of this

system depends on the size of the radiator piping and

other parts in the cooling system

We recommend not using water but cooling liquid that is

marketed for the use in combustion engines. Cooling liquid

protects the engine against frost to minus 25° C. Also it

protects the engine block against corrosion. Initially one

can fill the engine via the filling cap on the exhaust

manifold. Fill up till the level is just below the filling cap.

Additional filling of engine cooling system has to be done

via the expansion tank. When the engine is on

temperature the liquid will expand and the redundant liquid

will be pressed into the expansion tank. This tank has to

be filled up till the mark. On the tank is an overflow

connection. This connection can be used to connect an

open hose to drain the overflow of the cooling liquid to

outside the vehicle.

When cooling liquid is not available clean fresh water

could be used with an additive of anti freeze. When using

water with anti freeze the right mixture has to be

calculated according to the information of the supplier of

the anti freeze.

The cooling liquid in the engine is pressurised. A high

pressure hose connects the manifold to the expansion

tank.