Service manual

DRIVE SYSTEMS

5 - 22 Single Stage Snowthrower Service Manual

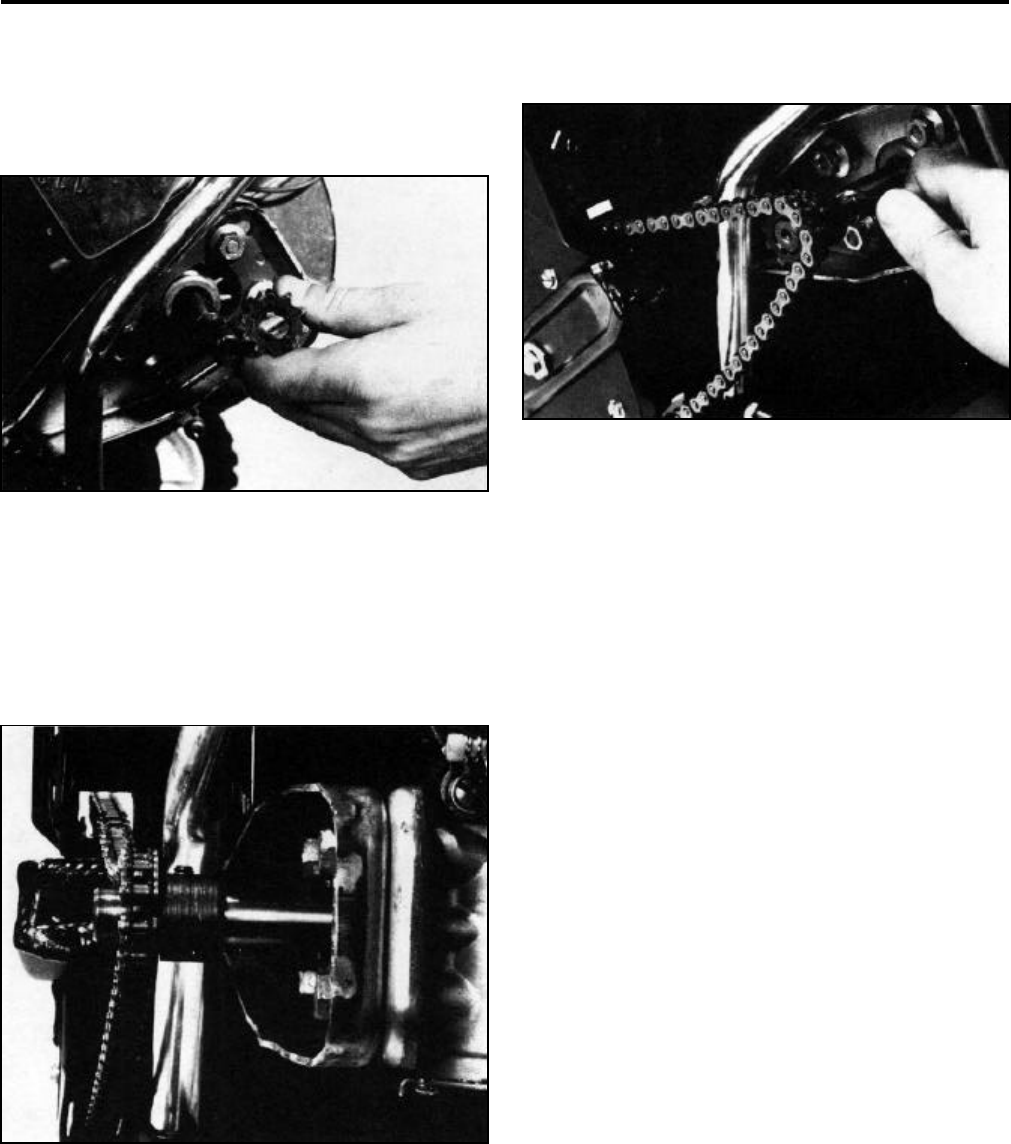

5. It will be necessary to align the keyway (slot) of

the crankshaft sprocket with the location key on

the crankshaft (Figure 111). Should the locating

key on the crankshaft show signs of wear, it may

be necessary to replace the key.

Figure 111 0217-062

6. From the rear of the unit, visually align the

crankshaft sprocket and chain with the impeller

sprocket. Once the sprocket and chain have been

installed (Figure 112) it is essential the chain be

aligned properly. If not, crankshaft or sprocket

damage will occur. Note: Figure 112 shows an

improperly aligned chain and sprocket.

Figure 112 0217-063

7. After aligning the chain, tighten the allen head

screws on the crankshaft sprocket (Figure 113).

Figure 113 0217-064

8. Pull the engine back until the chain is snug, with

no more than 1/8 inch deflection or slack (Figure

107).

9. Retighten the four bolts on sequence illustrated in

the Chain Adjustment procedure (Figure 108).

Torque to 170 - 220 in·lbs. Then tighten the

starter housing bolt, on the right side of the unit,

70 - 120 in·lbs. (Figure 106).

Note: Not following this tightening sequence can

lead to crankshaft breakage.

10. Replace the shrouding, chain guard, and spark

plug lead wire.

L.H. And R.H. (Left Hand And Right Hand) End Cap/

Bushing Replacement (1972-1980) 14” And 21”

Models

Note: Left hand end cap contains the impeller

sprocket. The proper chain adjustment, discussed

earlier, is essential to the service life of the impeller

sprocket. If the chain is too loose, the impeller

sprocket teeth can shear while operating under load.

Also, when the chain is loose, the bushings can

“wallow” (become oval shaped) out. To replace,

proceed with the following:

1. Refer to "Crankshaft Sprocket Replacement (all

models)" on page 5 - 21. Complete steps 1 and 2.