Manual

When picking Win-Holt Equipment you should review not only the carts and racks

but the casters on the units. You may find you need a caster other than what is on

the rack currently. We can upgrade any cart or rack for your needs based on your

environment. We have included in this section not only all the casters we offer but

detailed information from Floor Surfaces, Operating Environments, to the weight ca-

pacities of the casters we offer. If we do not have the caster that is right for your en-

vironment in stock or on these pages we can source the right caster for your

equipment. Several things need to be considered when picking a caster. Over the

next few pages we will explain each area you need to consider when choosing a

caster.

Load Capacity - Load capacity can be described as the maximum rolling capacity

of the equipment based on what you will place on that equipment.

Load capacity per caster can be determined as follows:

(Cart Weight + Maximum Load Placed on Cart)

Load Capacity = --------------------------------------------------------------

Number of Casters on Cart

Example:

75 + 800 / 4 = 219 lbs per caster

We advise using your maximum load that might be used on the cart and not the av-

erage weight. The greater the weight the larger the wheel size should be to distrib-

ute the weight evenly. Always by a caster with a higher rating than the load

capacity formula. In our example of 219 lbs per caster you should go with a caster

of at least 250 lbs. rolling capacity.

Wheel Mounting-The majority of Win-Holt equipment uses a stem caster of some type or plate caster. When selecting

new wheels, for equipment please review the mounting type to select the appropriate caster.

Ease of Rolling-Many factors will determine how easy your product will roll from floor conditions and surfaces to the total

weight but what type of bearing your caster have will make a large difference in the ease of rolling.

We offer casters with

ball bearings, nylon bearings, and roller barings.

Plain Bearings / Nylon Bearings are use where light duty carts and equipment are used.

Ball Bearings roll easier and carry more weight than plain bearings.

Roller Bearings carry heavier load capacities than ball bearings.

Wheel Type Material - When protecting floors or rolling your carts across abrasive surfaces choose a softer caster. When

rolling your carts across smooth surfaces choose a harder caster. The larger the wheel the easier it will be to roll across

rougher surfaces and carrier greater loads.

WHEELS & CASTERS

PAGE

128

800.444.3595 I 516.921.0538 fax I www.winholt.com

Floor Surfaces Easy Reference Wheel Selection Guide Operating Conditions

Wheel Type

Capacity of each Temp Range

Durometer

Ratings

(lb) (kg) (Fahrenheit)

Polyurethane 150-1,000 68-454 -30° to +180° 95(±5)A

Solid Soft Rubber 75-400 34-181 -30° to +160° 75(±5)A

Solid Hard Rubber 100-500 45-227 -30° to +160° 75(±5)D

Polyolefin 100-850 45-385 -20° to +180° 65(±5)D

Mold-On Polyurethane 425-4,200 193-1,905 -30° to +180° 55(±5)D

Mold-On Rubber 200 / 1,700 91 / 771 -30° to +160° 75(±5)A

Phenolic 400 / 8,000 181 / 3,628 -45° to +250° 85(±5)D

Phenolic High Temp. 400 / 2,900 181 / 1,315 -45° to +475° 85(±5)D

Pneumatic 300-800 136 / 363 -20° to +160°

⎯

Semi-Pneumatic 150-450 68 / 204 -20° to +160°

⎯

Semi-Steel 200 / 3,000 91 / 1,361 -45° to +250°

⎯

How to choose a caster?

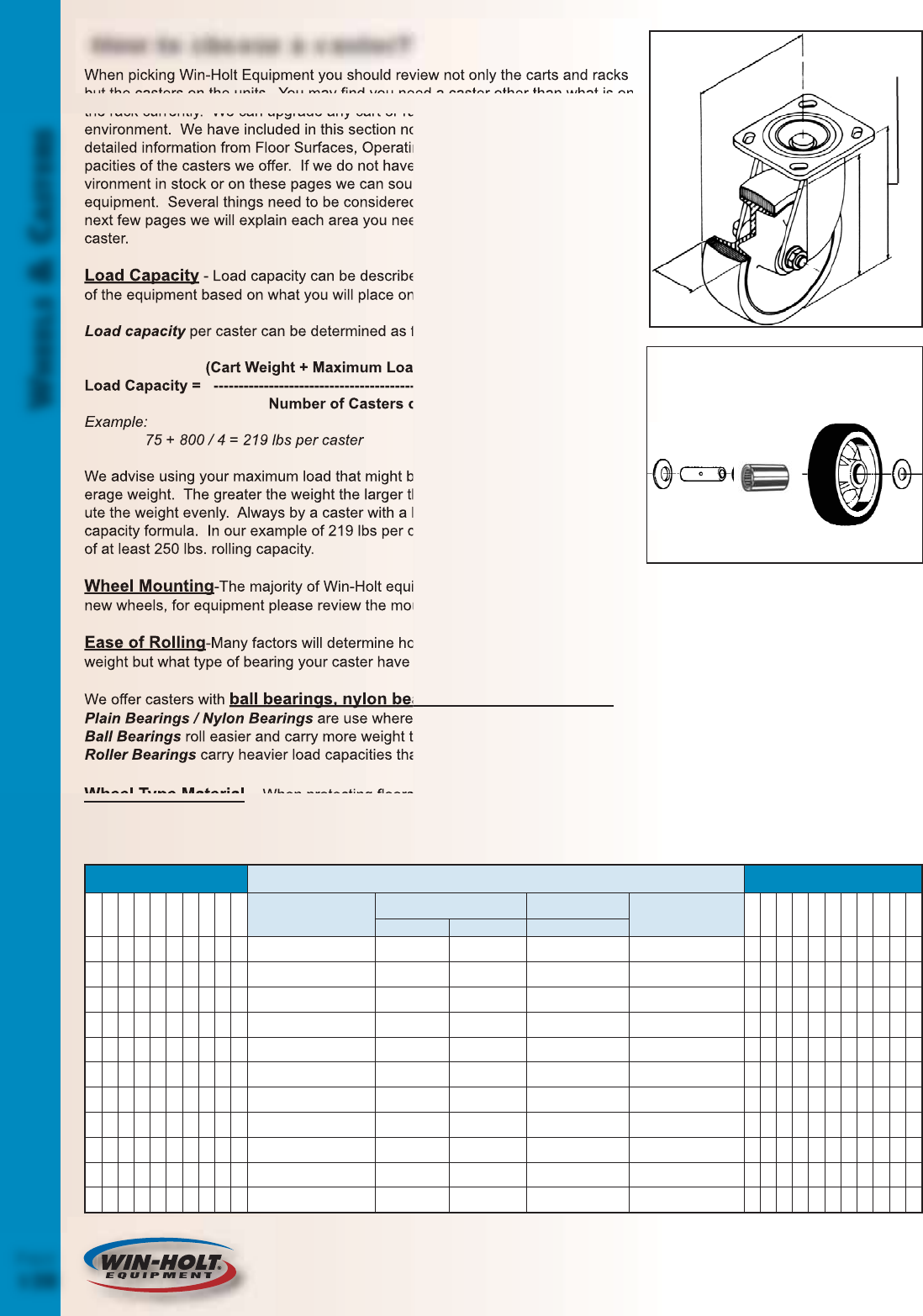

Plate

Caster

Terms

Swivel Radius

Tread

Width

This diagram represents a basic wheel as-

sembly. But this might vary from wheel to

wheel. Please consult the wheel specifica-

tions.

Wheel Terms

Retainer

Washer (2)

Spanner

Bushing

Cage Roller

Bearing

Wheel

Diameter