International, Inc. Planer User Manual

-36-

N(/()Fne\ijDXelXcD]^%j`eZ\*&'0

J<IM@:<

The feed rollers must be aligned correctly with the table

to maintain a smooth and straight feed.

KfZ_\Zbk_\]\\[ifcc\i$kf$kXYc\Xc`^ed\ek#[fk_\j\

jk\gj1

(. DISCONNECT THE PLANER/MOULDER FROM POWER!

). Remove the chip deflector lock pin, and set the chip

deflector aside.

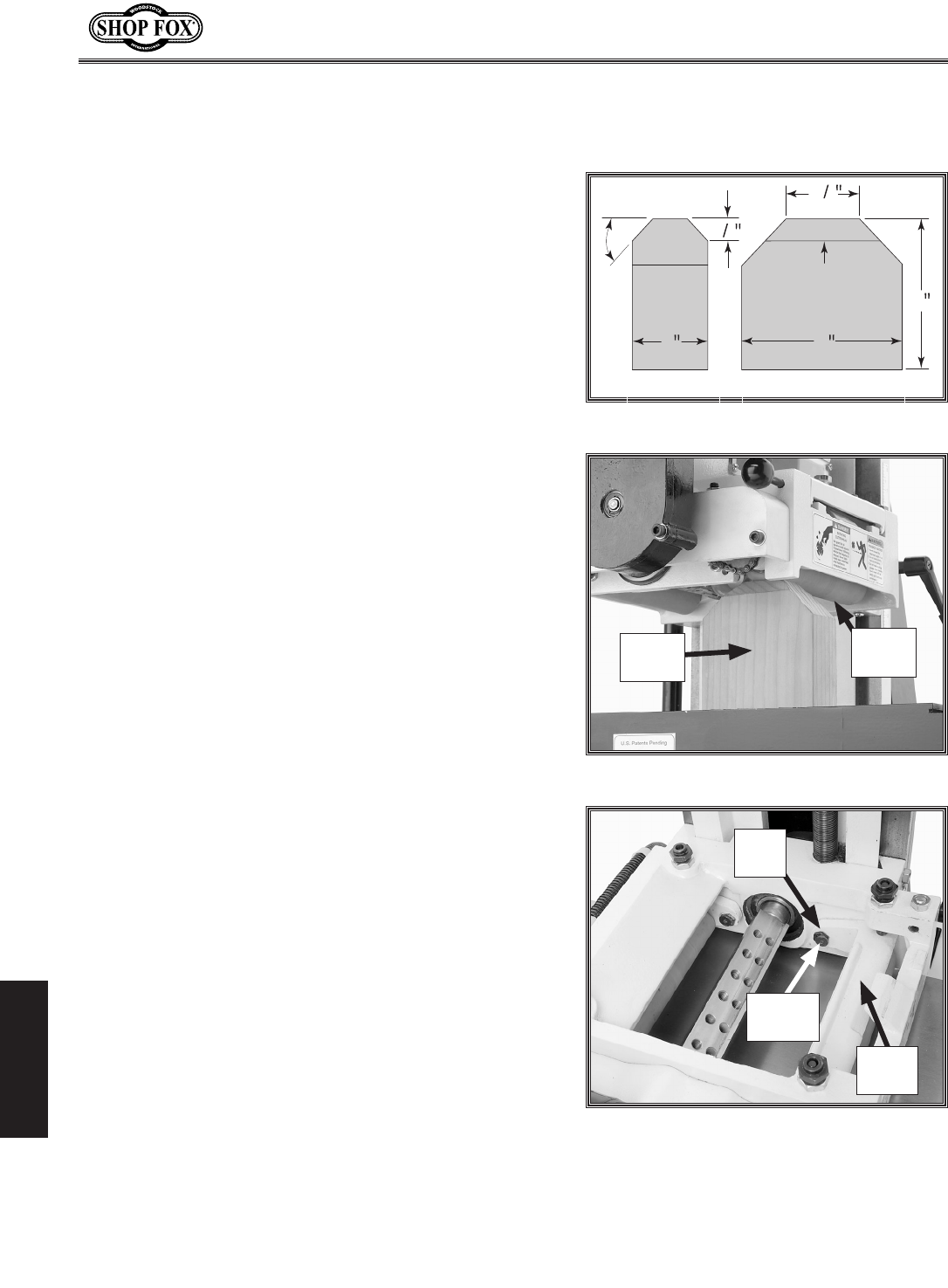

*. Refer to =`^li\54, and make a wooden gauge block

as outlined.

+. Place the finished block on the table, directly under

one end of the infeed roller (=`^li\55).

,. Lower the cutterhead housing so the infeed roller

barely touches the gauge block on the lowest end of

the roller (=`^li\55).

-. Slide the block over to the other end of the roller.

.. Using a set of feeler gauges, measure the gap

between the roller and the block.

—If the gap is more than 0.005", then proceed to Step

8 and adjust the swing arm lower so the gap is less

than 0.005".

/. Loosen the cap screw shown in =`^li\56, then

rotate the cam nut until the swing arm lowers and

the roller just touches the block.

0. Remove the gauge block and retighten the cap screw.

('. Check and adjust the outfeed roller next.

((. When both rollers are adjusted, check and adjust the

feed roller height and spring tension as outlined in

the Feed Roller Height and Spring Tension section

on Page 21.

(). When finished, reinstall the chip deflector.

=\\[Ifcc\i$kf$KXYc\

8c`^ed\ek

=`^li\55.Gauge block.

=`^li\56.Feed roller adjustment.

Cam

Nut

Cap

Screw

Gauge

Block

Feed

Roller

=`^li\54.Gauge block plans.

45°

2

4

4

1

1

2

1

2

Grain

Direction

Side View

Front View

Swing

Arm