International, Inc. Planer User Manual

-44-

N(/()Fne\ijDXelXcD]^%j`eZ\*&'0

G8IKJ

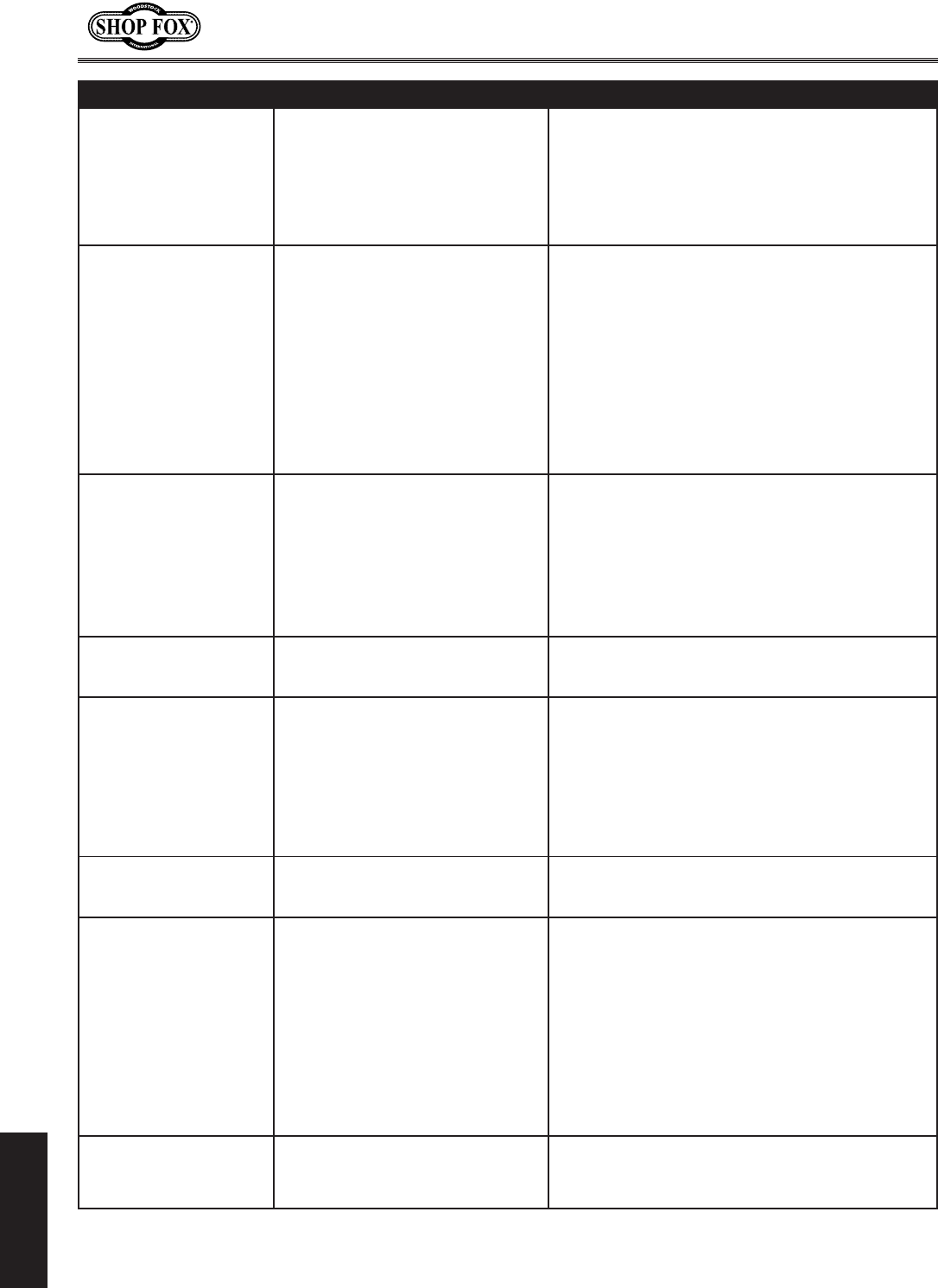

GIF9C<D GFJJ@9C<:8LJ< :FII<:K@M<8:K@FE

Excessive snipe (there is

a dip in the end of the

board that is uneven with

the rest of the cut).

1. One or both of the feed rollers are

set too low.

1. Adjust the feed rollers to the correct height (Page

21).

2. Feed roller springs are applying

too much roller pressure.

2. Reduce the feed roller spring tension (Page 21).

3. Workpiece is not supported as it

leaves the planer/moulder.

3. Hold the workpiece up slightly as it leaves the

outfeed end of the planer/moulder.

Workpiece stops/slows in

the middle of the cut.

1. Taking too heavy of a cut. 1. Raise headstock to take a lighter cut.

2. One or both of the feed rollers are

adjusted too high and workpiece

slips.

2. Lower the feed rollers (Page 21) to what is

specified in manual.

3. Feed roller spring tension is too

light.

3. Increase the feed roller spring tension (Page 21).

4. Guide or fence is interfering with

the workpiece travel.

4. Adjust guides or fence for adequate support

without workpiece interference.

5. Pitch and glue build-up on planer

components.

5. Clean internal cutterhead components with a

pitch/resin dissolving solvent.

Chipping (consistent

pattern).

1. Knots or conflicting grain direction

in wood.

1. Inspect workpiece for knots and grain direction;

only process clean stock (Page 23).

2. Nicked or chipped knife. 2. Replace the affected knife, or have it sharpened.

3. Feeding workpiece too fast. 3. Slow down the feed rate.

4. Taking too deep of a cut. 4. Take a smaller depth of cut. Always reduce cutting

depth when surface planing or working with hard

woods (Page 23).

Chipping (inconsistent

pattern).

1. Chips are not being properly

expelled from the cutterhead

area.

1. Provide a minimum of 400 CFM at the port, and

keep dust collector and ducting free of clogs and

restrictions.

Fuzzy grain. 1. Wood may have high moisture

content or surface wetness.

1. Check moisture content and allow to dry if

moisture is too high (Page 23).

2. Dull knives. 2. Replace the knives or have them professionally

sharpened.

3. Chips are not being properly

expelled from the cutterhead

area.

3. Provide a minimum of 400 CFM at the port, and

keep dust collector and ducting free of clogs and

restrictions.

Long lines or ridges that

run the length of the

board.

1. Nicked or chipped knife(s). 1. Replace or sharpen the knives.

Uneven knife marks, wavy

surface, or chatter marks

across the face of the

board.

1. Moulding knife is installed at

outboard side of cutterhead.

1. Install moulding knife at the inboard side of

cutterhead.

2. Feeding workpiece too fast. 2. Slow down the feed rate.

3. Feed roller spring tension is too

light.

3. Increase the feed roller spring tension (Page 21).

4. Knives are loose. 4. Remove the knives, clean knife mounting surfaces,

and reinstall knives.

5. Headstock is loose. 5. Adjust headstock gib (Page 38), and be sure to use

headstock lock lever.

6. Worn cutterhead bearings. 6. Replace cutterhead bearings.

Glossy surface. 1. Knives are dull. 1. Replace or sharpen the knives.

2. Feed rate too slow. 2. Increase the feed rate.

3. Cutting depth too shallow. 3. Increase the depth of cut.