Technical data

1514

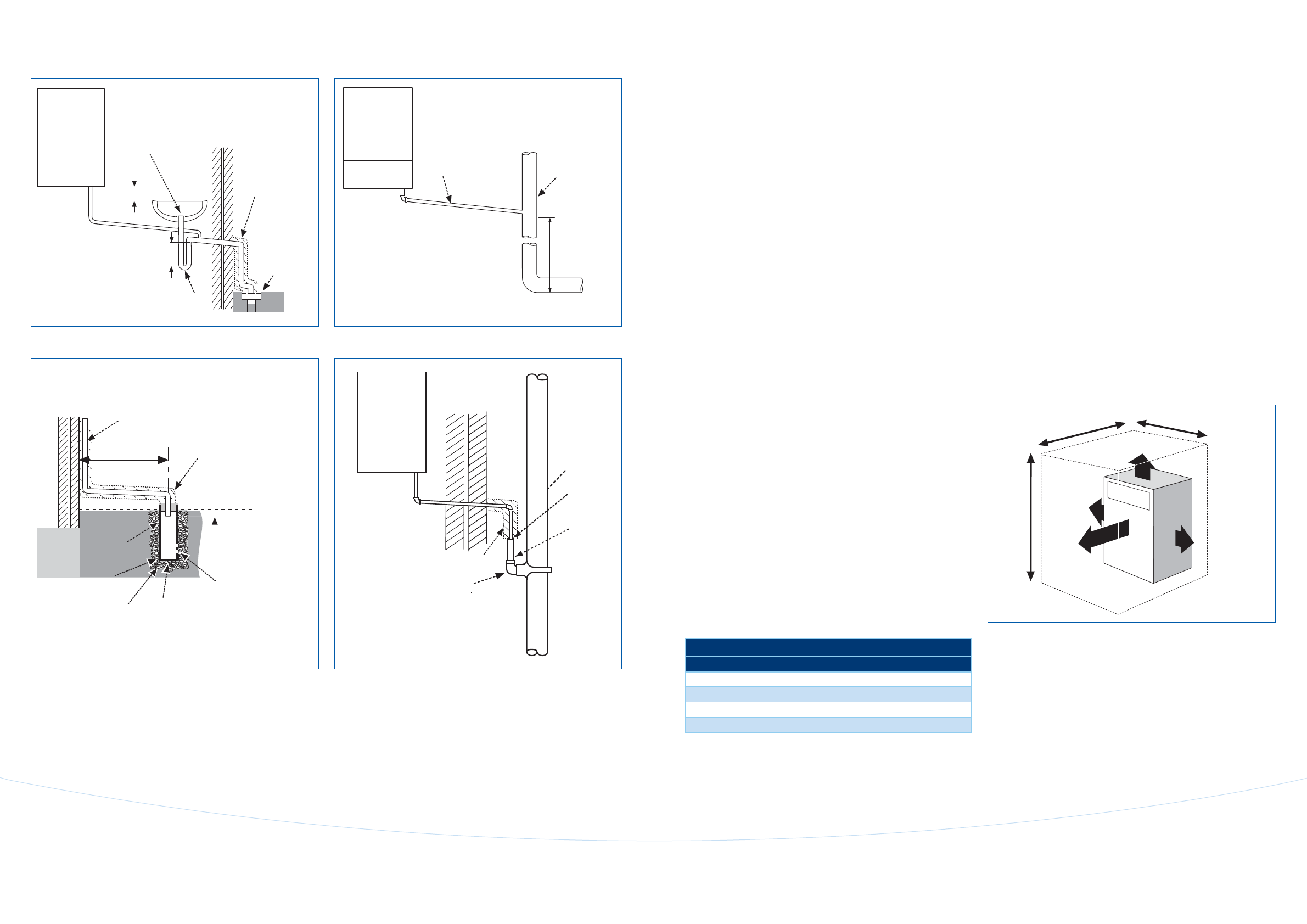

External condensate pipework

The Worcester Greenstar Highflow CDi appliances have a

condensate pump rather than a syphonic condensate trap.

Rather than the condensate constantly dripping into the

discharge pipe, the condensate is collected in the pump

which releases it in 100ml quantities. This will help prevent

freezing occurring.

Wherever possible the condensate discharge pipework

should be routed and terminated internally. Should this not

be possible, and the only available route is external, the

following conditions should be observed:

•

The pipework length should be kept to a minimum and

the route as vertical as possible

•

Where pipework could be subjected to extreme cold or

wind chill, a weather proof insulation should be used.

Alternatively, the condensate pipework could be

increased to a minimum 32mm.

Compartment installation

The appliance may be installed in any room, although

par

ticular attention is drawn to the requirements of the

IEE regulations applicable and in Scotland the electrical

provisions with respect to installation in a room containing

a bath or shower.

Air supply

1. The room in which the appliance is installed does not

require a dedicated air vent.

2. If the appliance is installed in a cupboard or

compartment with dimensions that allow the following

minimum clearances, then no ventilation is required:

Compartment installation

Position of appliance Min. unventilated clearance

In front 75mm*

Right side 100mm

Left side 100mm

Above flue elbow/casing 50mm

*75mm from an opening door. 600mm is required for servicing

Boiler location and clearances

This boiler is only suitable for installing internally within a

property at a suitable location on a fixed, rigid non-

combustible surface of at least the same size as the boiler

and capable of supporting the boiler weight.

Compartments: Follow the requirements of BS 6798 and

BS 5440 Part 2 and note:

•

Minimum clearances must be maintained

•

An access door is required to install, service and maintain

the boiler and any ancillary equipment

•

If fitting the boiler into an airing cupboard use a non-

combustible perforated material (maximum hole sizes of

13mm) to separate the boiler from the airing space.

Unvented compartment clearances

The diagram shows the minimum space required to install

and service the boiler inside an unvented compartment.

800mm

800mm

900mm

100mm**

200mm*

100mm**

50mm

*Space required for unvented areas with a removable door or panel.

**This space can be reduced to 50mm for one side only as along as both the side

clearances add up to the total of both the side measurements shown or more.

75 mm

min.

Condensing

boiler

22mm dia.

plastic pipe

75mm sink

waste trap

Open end of

condensate

drainage pipe

directly into

gully below

grating but

above water

level

Visible air break

at plug hole

100mm

Sink with

integral

overflow

Insulation

or increase

pipe size

Internal sink/washing machine drain

Soil & vent stack

22mm dia.

Minimum

450mm

and up t

o

3 storeys

Condensing

boiler

Invert

Soil and vent stack

Condensate drainage

pipe can be run above

or below ground

25mm

Bottom of

tube sealed

Limestone

chippings

Hole depth

400mm min.

by 300mm dia.

Drainage holes

22mm dia. condensate

drainage pipe, max external

length 3 metres

Diameter 100mm

min. plastic tube

500mm min.

Insulation or

increase pipe size

External condensate absorption point (unsuitable for clay soil types)

22mm dia. plastic

condensate drainage

pipe running through

the external wall

External

air break

Air gap

External drain

pipe into foul

water sewer

68mm dia.

PVC-u strap

on fitting

43mm 90°

M & F bend

Condensing

boiler

Insulation or

increase pipe size

External air break when using a foul water down pipe

Condensate termination and route