User Manual

YGE L-series from 40 to 160A electronic speed controller (ESC)

Technical data:

- The specified current is the maximum continuous full power current with adequate cooling.

- 2 to 6s LiPo, with under voltage protection by power reduction.

- 6 to 18 cells NiMH, with under voltage protection by power reduction.

- disconnectable under voltage detection.

- switching BEC: 5.5V, 3A continuous, 5A peak.

- Speed regulation (Governor mode).

- Soft start.

- Active free-wheel, allowing unlimited part load operation.*

- Automatic or 6 step adjustable timing.

- Continuously adjustable F3A brake.

- 3 steps adjustable regular back EMF brake.

- Switching rate: 8 to 16 kHz

- Speed limit: 240,000 RPM (2-Pole motors)

- Temperature and overload warning.

- Anti sparkling circuit: reduces connection sparkles

- Programming with the ProgCard II

Initial setup:

After connecting the battery (red = plus, black = minus)

you hear 3 descending tones. Subsequently, follows a

number of beeps according to the cell number of the

connected Lipo battery. In case the transmitter stick is in

throttle off, you hear now 3 ascending tones.

You need to connect the motor to hear the beeps, as it is

the motor itself which acts as a speaker.

--- The ESC is ready for use. ---

If the motor turns in the wrong direction, exchange simply

2 of the 3 motor wires.

Use only clean and tight gold connectors for motor and

battery. The 3.5 mm PK connectors have proven to be

the best choice from 30 to 80A. Pay attention for the

battery connector to choose a polarity safe system.

Exchange low-friction or oxidized plugs and sockets.

Because only tight sitting contacts will ensure a high

current flow, protect the speed controller against

dangerous voltage peaks and avoid disturbances. With

the 120A and 160FAI types please use you 5.5 and/or

6mm PK gold connectors, because the 3.5 and 4mm

connectors are only certified up to 80A. Here the motor

wires are usually shortened to the minimum and soldered

directly to the motor. On the other side, with all ESC

types, the entire wire length, from the controller to the

battery, may not exceed 20cm. If longer wires are

necessary, a Low ESR switching capacitor of 330µF/25V

should be soldered between plus and minus wires every

20cm. You might also consider using our capacitor

module YGE Cap´s typ 5. Likewise the motor wires can

be extended. Then please twist the 3 lines, in order to

minimize interference emission.

Note: Inverting the Battery polarity leads to heavy

damage and to the loss of warranty!!!

General Settings:

The speed controller has a fixed throttle curve setting, so

that with all usual transmitters the stop and full power points

are linearly connected. With all programmable transmitters,

the throttle range should be set to default (±100%), the

center point set to zero and throttle trim enabled.

Nevertheless, with some transmitter types the range needs

to be adjusted. For that the throttle endpoints have to be set

so that one notch before lowest stick position the motor is

stopped and that one notch before full power the motor is

actually at full power. Full power is indicated by the LED that

is completely turned off.

On delivery the Timing is adjusted to 18°, brake is set to mid

level, and the under voltage recognition adjusted to Lipo

mode 3.1 V.

If during spin up rpm variations (wowing or erratic sound) are

experienced, the timing must be increased. If no

improvement can be obtained at 30°, then the motor is

overloaded. Here a smaller propeller, a one cell smaller

battery or a stronger motor will help. If after motor stop you

hear 2 beeps repeating, it means that the battery voltage

dropped down below the setting value. Eventually try a cutoff

voltage of 2.9 or 3.0V per cell. If there is still no

improvement, then the battery is discharged or too weak, the

wires are too long or to small or a connector is out of order.

With an active brake you can hear these warning tones only

in windmill position. This is the small range on the throttle

stick between brake and motor start. You can reach this

position with 2 notches or with a high trim and a short gas

start.

If no automatic timing is wished, it can be adjusted according

to the following guideline.

Inrunner 0 to 12°

Outrunner 18 to 30°

If your motor manufacturer indicates a timing

recommendation, it is of course preferable to use it.

Basic rule: the higher the timing the higher the full power

rpm.

only for pylon

and hotliner

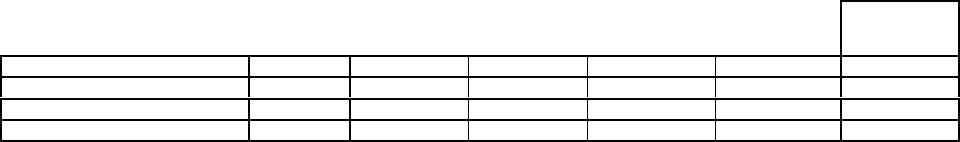

Type 40A 60A 80A 100A 120A 160 FAI

Overall dimensions in mm 62 x 25 x 8

62 x 25 x 8

70 x 25 x 11 70 x 25 x 11 70 x 25 x 12 70 x 25 x 14

Weight in g without/with wires 19 / 35 19 / 35 28/55 29/69 31/71 39/79

Cable diameter Battery/Motor 2.5 ²/2.5 ² 2.5 ²/2.5 ² 4² / 2.5² 4² / 4² 4² / 4² 4² / 2.5²